Understanding Modern Manufacturing Technologies

The manufacturing landscape has evolved dramatically in recent decades, with two technologies standing at the forefront of innovation: cnc machining and 3D printing. These revolutionary production methods have transformed how we create everything from aerospace components to medical devices. As industries continue to advance, the choice between these technologies becomes increasingly crucial for manufacturers, engineers, and product developers.

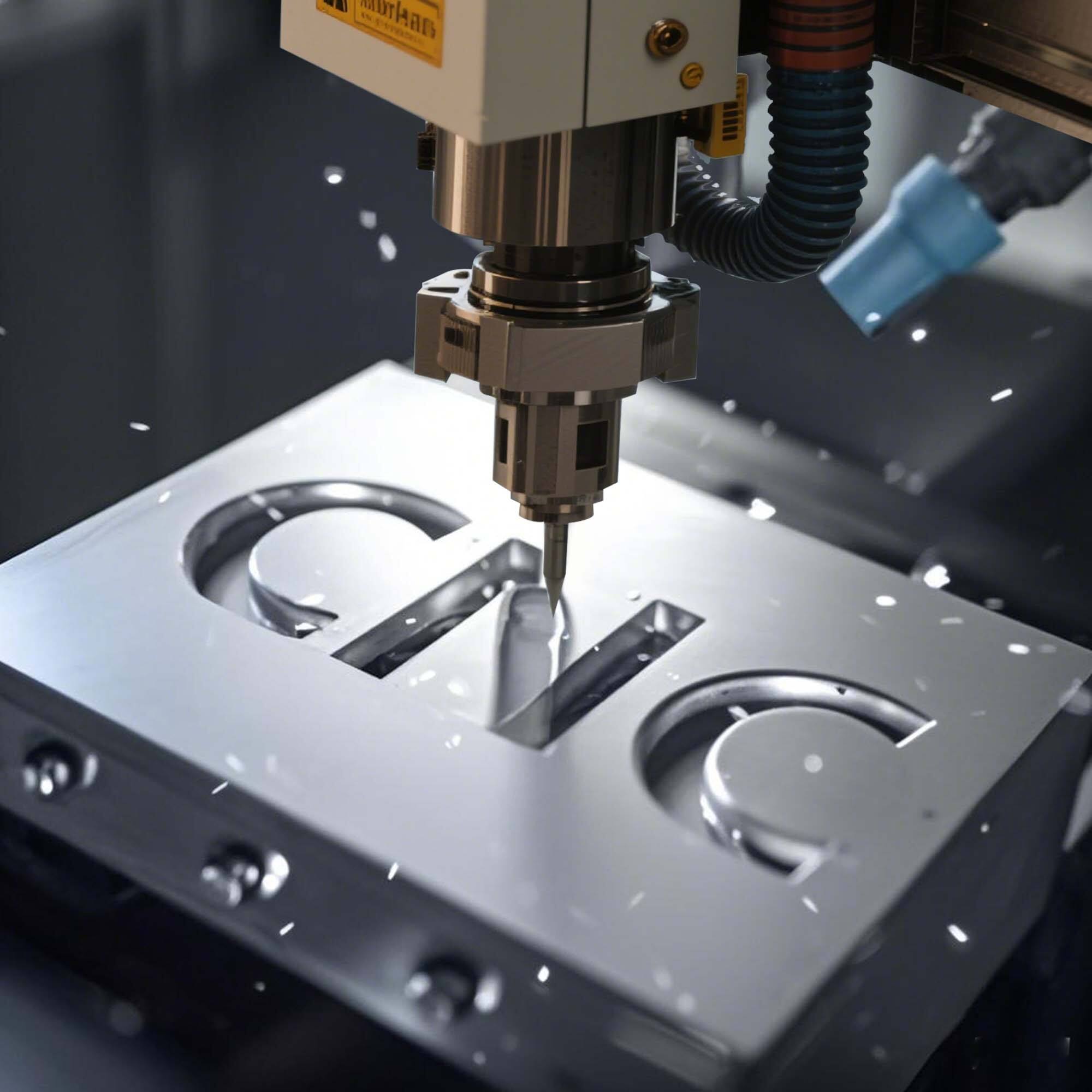

While both technologies serve the purpose of creating physical objects from digital designs, they operate on fundamentally different principles. CNC machining follows a subtractive manufacturing process, where material is precisely removed from a solid block to create the desired shape. In contrast, 3D printing builds objects layer by layer in an additive process. Understanding these distinct approaches is essential for making informed manufacturing decisions.

The Power of CNC Machining Technology

Precision and Accuracy in Manufacturing

CNC machining excels in delivering exceptional precision and repeatability. Modern CNC machines can achieve tolerances as tight as ±0.0001 inches, making them ideal for creating high-precision components. This level of accuracy is particularly crucial in industries like aerospace and automotive manufacturing, where even minimal deviations can affect performance.

The consistency of cnc machining ensures that each produced part meets exact specifications, whether it's the first piece or the thousandth. This reliability stems from the rigid structure of CNC machines and their sophisticated control systems, which execute precise movements based on computer-generated instructions.

Material Versatility and Strength

One of the most significant advantages of cnc machining is its ability to work with an extensive range of materials. From metals like aluminum and steel to plastics and composites, CNC machines can effectively process virtually any solid material. This versatility makes cnc machining invaluable across various industries, from medical device manufacturing to defense applications.

The finished products from CNC machining typically exhibit superior structural integrity compared to 3D printed parts. Since they're carved from solid blocks of material, they maintain the original material's properties throughout the entire component, resulting in better strength and durability.

The Rise of 3D Printing Technology

Design Freedom and Complex Geometries

3D printing's layer-by-layer approach enables the creation of intricate geometries that would be impossible or prohibitively expensive with traditional cnc machining. This technology allows for internal channels, honeycomb structures, and organic shapes that can optimize product performance while reducing weight.

The ability to print complex designs without additional cost has revolutionized prototyping and small-scale production. Designers can quickly iterate through multiple versions of a product, testing different features and improvements without the setup costs associated with traditional manufacturing methods.

Cost-Effectiveness for Small Batches

When it comes to producing small quantities or unique items, 3D printing often proves more economical than cnc machining. The elimination of tooling costs and the ability to start production immediately from a digital file makes it particularly attractive for prototyping and customized products.

However, as production volumes increase, the cost advantage of 3D printing diminishes. The slower production speed and higher material costs can make it less competitive than cnc machining for larger production runs.

Comparing Key Performance Factors

Surface Finish and Post-Processing

CNC machining typically produces superior surface finishes right off the machine. The cutting tools and precise control systems can achieve smooth surfaces that often require minimal post-processing. In contrast, 3D printed parts frequently show visible layer lines and may need extensive finishing work to achieve comparable quality.

While cnc machining might require deburring or polishing in some cases, the post-processing requirements are generally less intensive than those for 3D printed parts. This factor can significantly impact the total production time and cost when considering the entire manufacturing process.

Production Speed and Scalability

For large production runs, cnc machining often proves more efficient than 3D printing. Once properly set up, CNC machines can produce parts rapidly and continuously, with minimal operator intervention. The ability to run multiple machines simultaneously with consistent quality makes scaling production straightforward.

3D printing, while excellent for prototyping and small batches, typically requires longer production times per part. The layer-by-layer building process is inherently slower than the material removal approach of cnc machining, particularly for larger or more complex components.

Making the Right Choice for Your Project

Production Volume Considerations

When deciding between cnc machining and 3D printing, production volume plays a crucial role. For high-volume manufacturing, the speed and consistency of cnc machining often make it the more practical choice. The initial setup costs can be effectively amortized across larger production runs, resulting in lower per-unit costs.

Small batch productions or one-off projects might benefit more from 3D printing's flexibility and lower startup costs. The ability to produce parts without tooling investments can make it more economical for limited runs, especially when dealing with complex geometries.

Application-Specific Requirements

The intended application of the final product should heavily influence the manufacturing method selection. Parts requiring high structural integrity or precise tolerances typically favor cnc machining. The consistent material properties and superior surface finish make it ideal for functional components in demanding applications.

Projects that prioritize weight reduction, unique geometries, or rapid design iterations might find 3D printing more suitable. The technology's ability to create hollow structures and complex internal features can provide advantages in specific applications where traditional manufacturing methods fall short.

Frequently Asked Questions

What are the primary cost factors in CNC machining?

The main cost factors in cnc machining include material costs, machine time, setup and programming time, and tooling expenses. Labor costs for machine operation and potential post-processing requirements also contribute to the overall expense. However, these costs typically decrease per unit as production volume increases.

How does material selection differ between CNC machining and 3D printing?

CNC machining can work with virtually any solid material, including metals, plastics, and composites, while 3D printing is limited to specific materials designed for additive manufacturing. The material properties in cnc machined parts are typically more consistent and predictable compared to 3D printed alternatives.

What determines the suitable technology for my project?

The choice between cnc machining and 3D printing depends on several factors, including production volume, required accuracy, material requirements, geometric complexity, and budget constraints. Complex parts needed in small quantities might favor 3D printing, while high-volume production of precise components typically benefits from cnc machining.