Understanding the Critical Role of Component Quality in Modern CNC Operations

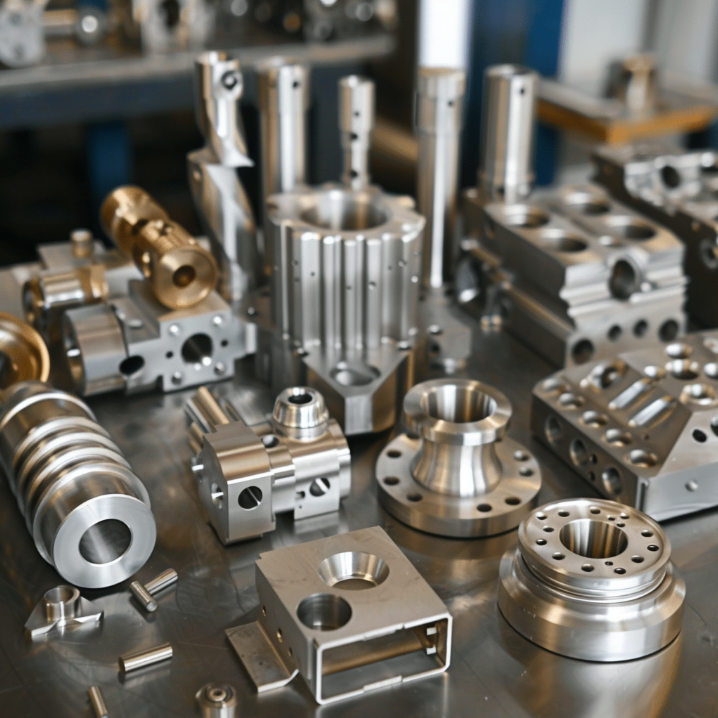

In the precision-driven world of manufacturing, CNC machining performance stands at the forefront of production excellence. The relationship between part quality and machine efficiency has never been more crucial than in today's competitive industrial landscape. When manufacturers invest in superior components, they're not just buying parts – they're investing in the future of their operations, ensuring consistent output and minimizing costly downtime.

The manufacturing industry has witnessed a dramatic evolution in CNC technology over the past decade. With tolerances becoming tighter and production demands increasing, the quality of individual machine components has emerged as a defining factor in overall system performance. This comprehensive analysis explores how high-quality parts directly influence CNC machining performance and why this understanding is essential for modern manufacturing success.

Essential Components that Drive Machine Efficiency

Precision Spindle Systems and Their Impact

At the heart of any CNC machine lies its spindle system, where quality becomes immediately apparent in day-to-day operations. Premium spindle components, including bearings, motors, and cooling systems, contribute significantly to enhanced CNC machining performance. High-grade spindles maintain tighter tolerances, produce better surface finishes, and demonstrate remarkable longevity compared to their lower-quality counterparts.

Modern spindle systems incorporating ceramic bearings and precision-balanced components can achieve higher speeds while maintaining stability. This advanced engineering translates directly into improved cutting capabilities and reduced vibration, ultimately leading to superior part quality and extended tool life.

Linear Motion Components and Precision

The accuracy of linear motion systems fundamentally determines a CNC machine's capability to produce precise parts. Premium linear guides, ball screws, and bearing blocks ensure smooth, accurate movement and positioning. These components must maintain their precision under continuous operation, making material quality and manufacturing tolerance critical factors in their performance.

When manufacturers opt for high-quality linear motion components, they experience better positioning accuracy, reduced maintenance requirements, and improved overall CNC machining performance. The investment in superior components pays dividends through consistent accuracy and reduced wear over time.

Performance Metrics and Quality Correlation

Accuracy and Repeatability Improvements

High-quality parts directly influence a machine's ability to maintain precise tolerances and consistent output. Premium components contribute to better positioning accuracy, with some systems achieving repeatability within microns. This level of precision is essential for industries such as aerospace, medical device manufacturing, and high-end automotive production.

Statistical analysis shows that machines equipped with superior components demonstrate up to 40% better accuracy over extended operating periods compared to those with standard parts. This improvement in precision directly impacts part quality and reduces scrap rates, delivering substantial cost savings over time.

Longevity and Maintenance Intervals

The durability of high-quality components significantly extends maintenance intervals and reduces unexpected downtime. Premium parts, manufactured with superior materials and tighter tolerances, typically exhibit wear rates 50-60% lower than standard components. This increased longevity translates into fewer maintenance cycles and more productive machining hours.

Manufacturing facilities that invest in quality components often report extended service intervals and reduced emergency maintenance requirements. This improved reliability directly enhances CNC machining performance by maintaining consistent production schedules and reducing costly interruptions.

Economic Implications of Component Quality

Return on Investment Analysis

While premium components command higher initial prices, their impact on long-term CNC machining performance creates compelling economic benefits. Advanced manufacturing facilities report that investing in high-quality parts can reduce overall operating costs by 15-25% over a five-year period. These savings come from reduced maintenance requirements, lower energy consumption, and improved production efficiency.

The financial advantages extend beyond direct cost savings. Enhanced machine reliability leads to better delivery performance, increased customer satisfaction, and stronger market positioning. These factors contribute to a robust return on investment that justifies the initial premium for quality components.

Productivity and Output Quality

Superior components directly influence production capacity and part quality. Machines equipped with high-grade parts consistently demonstrate higher throughput rates while maintaining precise tolerances. This improved performance allows manufacturers to take on more demanding projects and compete effectively in high-value markets.

The impact on product quality is equally significant. Manufacturing operations using premium components report rejection rates below 1%, compared to industry averages of 3-5%. This improvement in yield represents substantial cost savings and enhanced customer satisfaction.

Future Trends in Component Quality and Machine Performance

Technological Advancements

The future of CNC machining performance is closely tied to emerging technologies in component manufacturing. Advanced materials, including new alloys and composites, are being developed to enhance durability and precision. Smart components with integrated sensors are enabling predictive maintenance and real-time performance monitoring.

These innovations are reshaping expectations for machine performance and reliability. Manufacturers who embrace these advanced components position themselves at the forefront of manufacturing capability and efficiency.

Industry Standards Evolution

Global manufacturing standards continue to evolve, pushing the boundaries of component quality and performance requirements. New specifications for precision, durability, and energy efficiency are driving innovation in component design and manufacturing. This evolution ensures that high-quality parts will play an increasingly crucial role in CNC machining performance.

Industry leaders are actively participating in the development of these standards, recognizing that superior component quality is essential for meeting future manufacturing challenges.

Frequently Asked Questions

How do high-quality components affect machine tool life?

Premium components significantly extend tool life by reducing vibration, maintaining proper alignment, and ensuring consistent cutting conditions. This results in 30-50% longer tool life and reduced tooling costs.

What is the typical payback period for investing in premium CNC components?

Most manufacturers observe a return on investment within 12-18 months through reduced maintenance costs, improved productivity, and decreased downtime. The exact period varies based on usage patterns and application requirements.

How can manufacturers verify component quality before purchase?

Quality can be verified through certification documentation, material testing reports, and performance guarantees from reputable suppliers. Working with established manufacturers who provide detailed specifications and testing data ensures component reliability.

Table of Contents

- Understanding the Critical Role of Component Quality in Modern CNC Operations

- Essential Components that Drive Machine Efficiency

- Performance Metrics and Quality Correlation

- Economic Implications of Component Quality

- Future Trends in Component Quality and Machine Performance

- Frequently Asked Questions