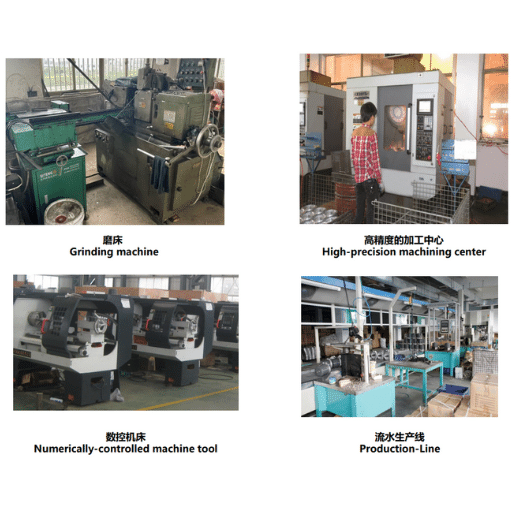

5. Quality control measures: To ensure the components produced meet up with the required standards of precision and quality, there can be no compromise at any stage in our strict quality control process at Jinxi.

Frequently Asked Questions

If you want to know more about CNC Turning Service

Q: What is a CNC turning service and how does it work?

A: It is a method of machining where the material is removed by a cutting tool from revolving workpiece until it takes the shape of intended design. The process can be carried out on a computer numerical control lathe or turning machine, which follows a pre-programmed sequence and controls its operations through computer software. This technique is good at making intricate parts having cylindrical details.

Q: What are the advantages of CNC turning over traditional machining?

A: Some benefits of CNC turning include greater accuracy, productivity, and repeatability. Machines used for this purpose can create complex components with close tolerances much faster than manual lathes. Moreover, these machines reduce mistakes made by humans, resulting in uniform production quantities for metals, including plastics such as ABS or Nylon.

Q: What materials can be used with CNC turning machines?

A: CNC machines designed for turning are able to handle many types of substances like metals (e.g., stainless steel, aluminum, brass), and plastics (e.g., polycarbonate). With such adaptability, it becomes possible to manufacture custom turned parts using different materials applicable in various industries.

Q: How does the surface finish of a CNC turned part compare with other machining processes?

A: Frequently, the surface finish achieved after completion of the turned component is better than that obtained in alternative machining methods. Another important thing about cnc lathe is that it allows controlling surface roughness so that tool marks become invisible or absent at all. In addition finishes may be modified according to specific needs by changing parameters during cnc machining operation itself.

Q: What are common applications of CNC turning?

A: Various sectors utilize CNC lathe services extensively, including the aerospace and automotive industry, medical sector electronics, etc., where shafts, pulleys, bushings, fasteners, etcetera could be produced. Both prototypes and mass-produced items require high precision with cylindrical features, thus making this type of machining suitable for both.

Q: How does one determine the most appropriate CNC turning service provider to select?

A: Always consider specialization, capabilities, and equipment when choosing a CNC turning service provider. Ensure that they have dealt with materials similar or identical to those you plan on using before. Try as much as possible to know their turnaround time especially if it is needed urgently for rapid prototyping or production parts. Also look out for companies with an instant online quoting system because it saves time in the process of getting quotes.

Q: Can other processes be combined with CNC turning to create more complex parts?

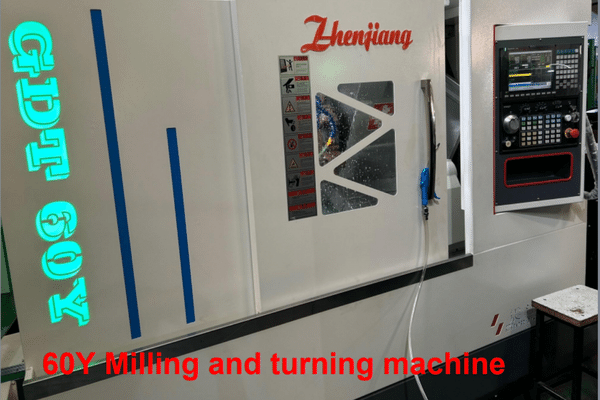

A: Yes, other processes such as milling can be combined with CNC turning to increase complexity of part geometry that cannot be achieved through only turning. Off-axis holes slots milled surfaces etcetera are made possible by this capability thereby enhancing versatility in custom projects where both milling and turning operations are required.

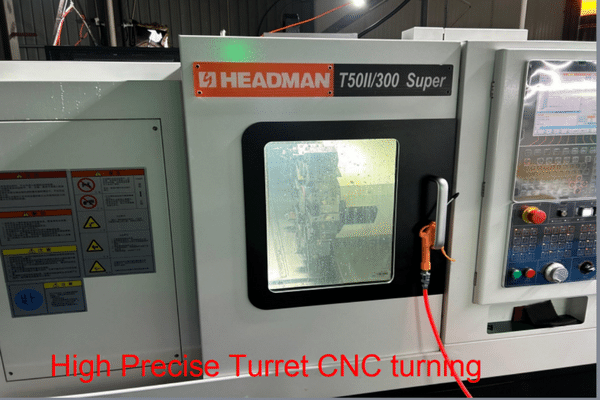

Q: What are the different types of CNC Turning Centres? How do they differ from each other?

A: There are various types of CNC Turning Centers, including horizontal, vertical, fixed headstock, and sliding headstock. Multi-axis ones can perform more complicated operations like taper cutting and shape machining because they have extra axes than regular machines. The size, complexity, and volume of production determine which type is suitable for a given job.

Q: What is Rapid Prototyping using CNC Turning?

A: Rapid prototyping through cnc.turing refers to the quick creation of physical models from digital designs using a lathe machine which is controlled numerically. It helps engineers and designers assess part functionality and aesthetics at earlier stages in design cycles. This technique is fast and accurate and works with many materials, enabling speedy iteration enhancements, and is thus valued highly.

Q: How Do I Get Instant Quote For My Project With You Guys?

A: Many websites offer instant quote systems so do some suppliers but others may take longer times.. To get such quotes all you need do is; upload your CAD files, specify material finish quantity requirements then wait a little bit as the system analyses design for pricing based on complexity of cnc.turning process and material chosen. This allows you to easily compare costs between different providers for your turned parts