What is sheet metal fabrication?

Sheet metal fabrication is the process of forming, cutting, and assembling metal sheets into various shapes and structures. It involves several techniques such as cutting, bending, and welding,surface treatment to create finished products from sheet metal materials. Sheet metal, typically made from materials like steel, aluminum, or copper, is widely used in various industries for manufacturing parts and components of machines, vehicles, appliances, and more.

Starway's online sheet metal fabrication services offer a comprehensive and efficient solution for producing parts based on 3D CAD files or engineering drawings. Starway provide a variety of materials, including stainless steel,aluminum, brass, steel, and stainless steel, and cover multiple fabrication processes such as stamping, cutting, bending, and welding. Our services also include assembly, such as installing PEM inserts, design packaging drawings and packaging services. Starwaty can accommodate both low-volume prototypes and volume production, offering competitive custom pricing for sheet metal fabrication. Starway is committed to bringing your idea to life.

Our Sheet Metal Fabrication Factory

Our Sheet Metal Processing Technology

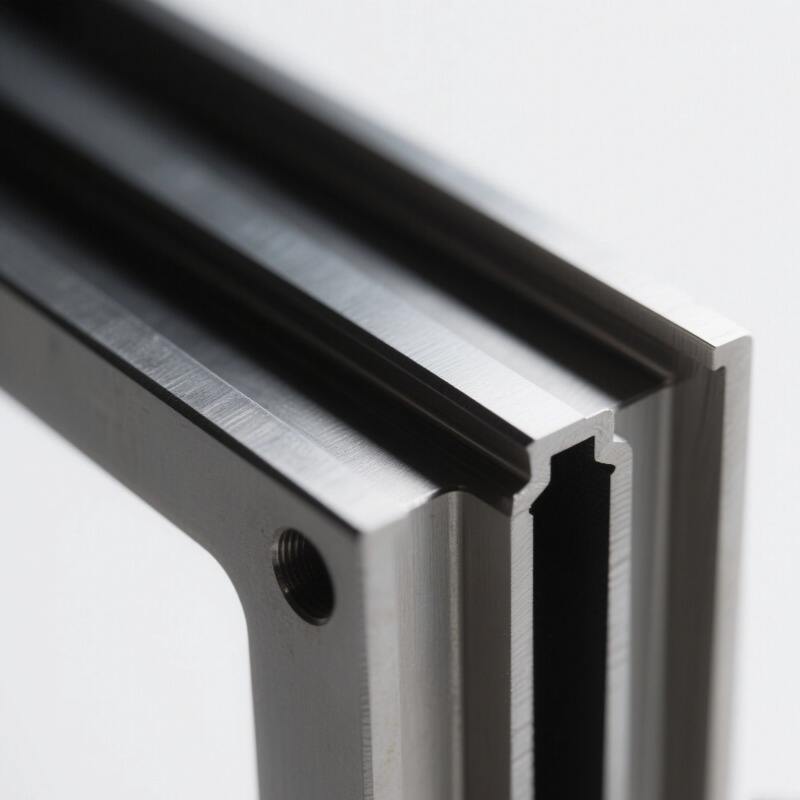

Sheet metal is cut into the desired shape and size using various methods including shearing, laser cutting, plasma cutting, or water jet cutting. Precision cutting is essential to ensure accurate dimensions and smooth edges.

The sheet metal is bent into specific angles and shapes using press brakes or other bending machines. This process requires precise control of force and angle to achieve the desired bend without causing deformation or cracking.

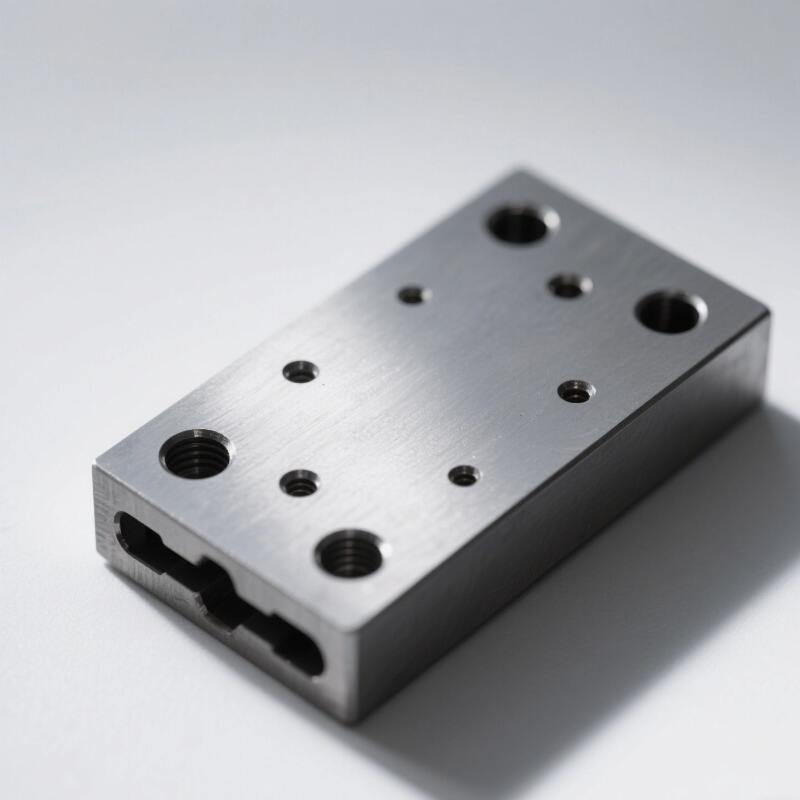

Additional forming processes such as rolling, punching, or stamping may be used to create complex shapes, contours, or features on the sheet metal.

Welding is used to join multiple pieces of sheet metal together. Common welding techniques include spot welding, MIG welding, TIG welding, and seam welding. Welded joints must be strong and durable to withstand the intended application.

After fabrication, the sheet metal may undergo surface treatments such as painting, powder coating, or plating to enhance its appearance and protect it from corrosion.

The fabricated components are assembled together to create the final product. This may involve fastening, riveting, or welding the components together.