Capabilities of Acrylic (PMMA) CNC Machining Service

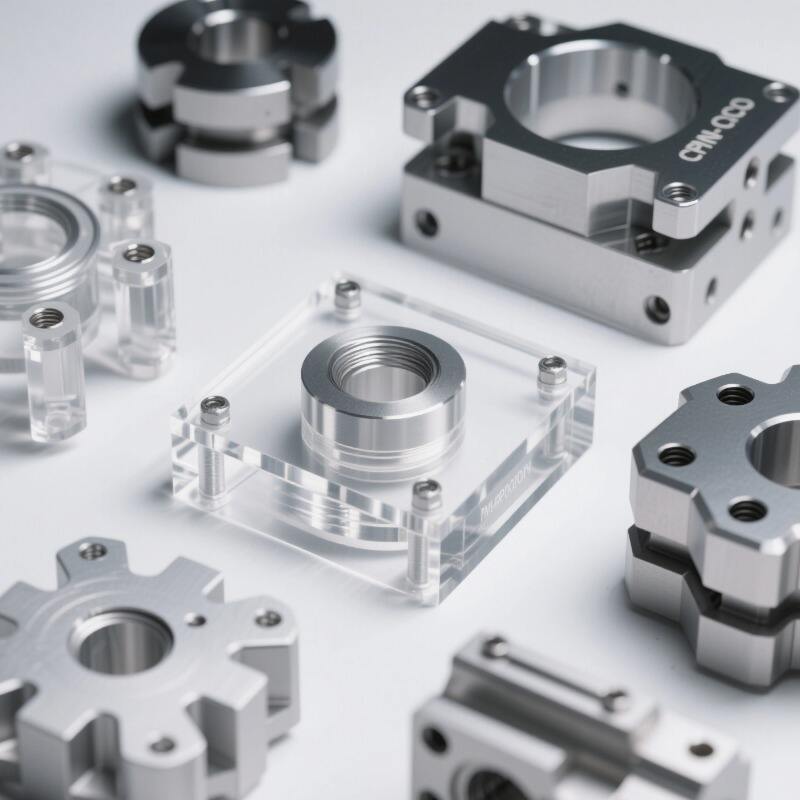

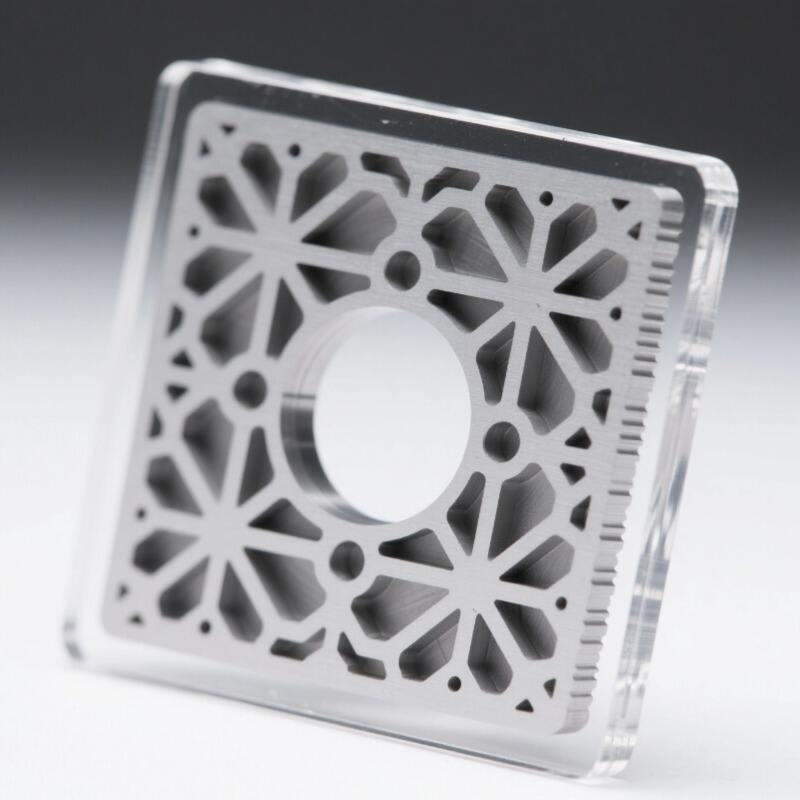

Acrylic’s use in CNC Machining guarantees accurate cutting, low-cost production, and flexibility in finishing. This material is lightweight and can resist UV rays, making it suitable for many sectors, including health care and sign-making industries. However, one should also take into account that acrylic’s brittle nature may lead to sharp edges while maintaining high precision.

Acrylic CNC Machining: Precision Manufacturing of PMMA Components with a Focus on Quality Display

Acrylic (PMMA) CNC Machining: Available Material for Precision Machining

Polymethyl methacrylate (PMMA) or acrylic is an adaptable material that is extensively used in computerized numerical control (CNC) machining. This material became popular because of its outstanding optical clarity, impact strength, among other mechanical properties, and ease of processing. The reliability and precision provided by Acrylic CNC machining make it one of the most suitable materials for different applications.

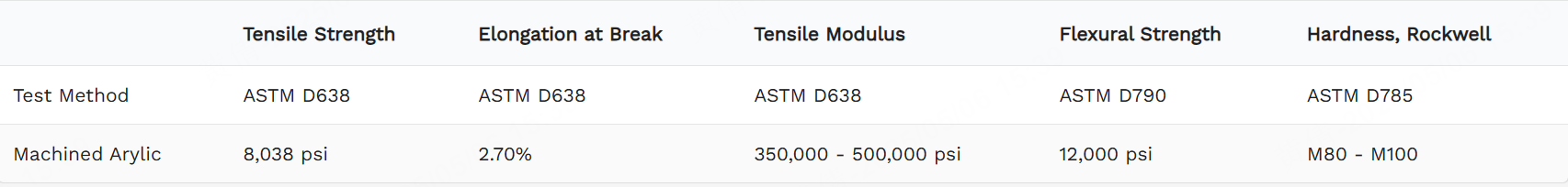

Acrylic (PMMA) Material Properties for CNC Machining

Why choose Jinxi's Acrylic (PMMA) CNC Machining

1. Exactness: Jinxi’s CNC Machining guarantees accurate results by using highly developed technology.

2. Long Lasting: Acrylic (PMMA) material is long lasting and can be used for machined parts.

3. Flexibility: Complex designs and shapes are made possible during the CNC machining process.

4. Beauty: Acrylic (PMMA) makes products look sleek and modern.

5. Time-Saving: Apart from ensuring quality, Jinxi’s CNC Machinin Service saves time and cuts down costs in the production process.