5. Trustworthiness: Every job is done consistently well so you can always count on us doing an excellent job each time we work together!

Frequently Asked Questions

If you want to know more about PTFE(Teflon) CNC Machining

Q: What is PTFE (Teflon), and why is it commonly used in CNC machining?

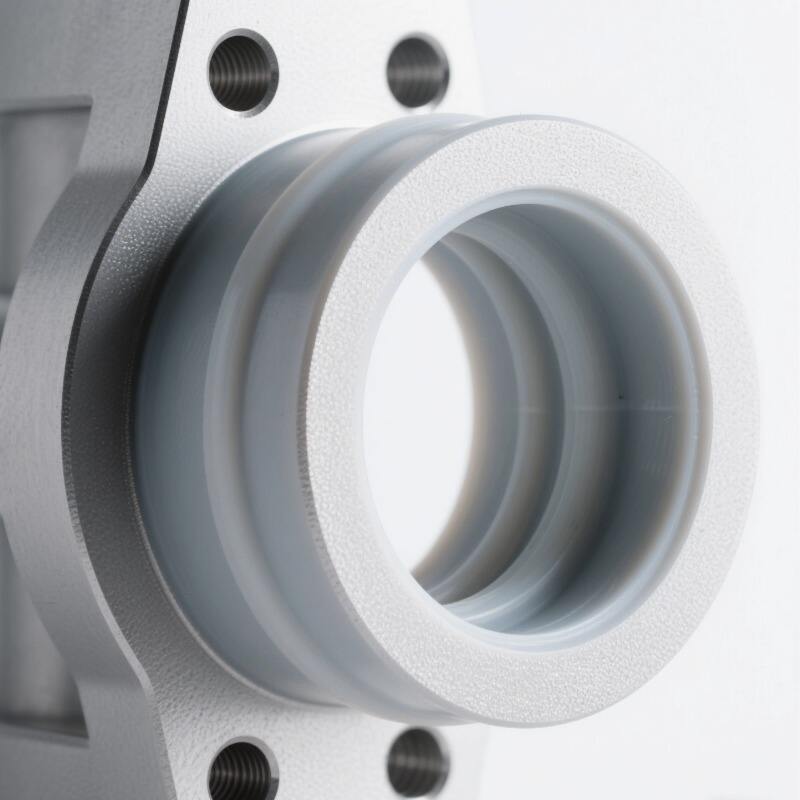

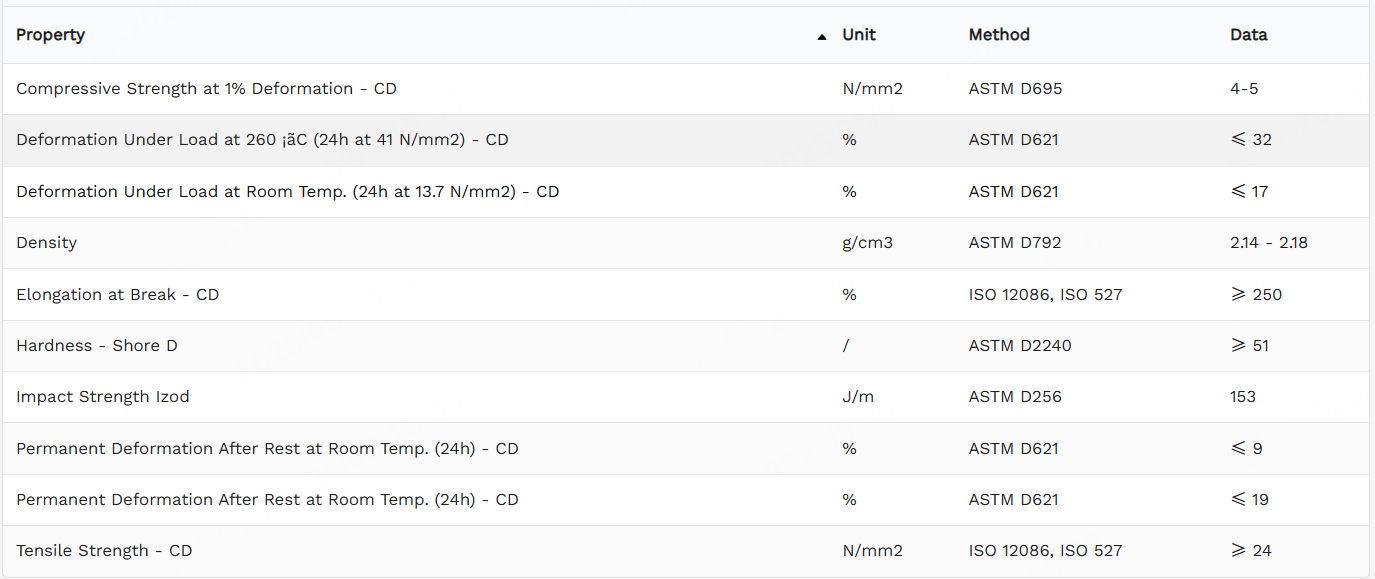

A: PTFE, or Teflon, also known under its brand name, is a thermoplastic fluoropolymer that is famous for its high resistance to chemicals, its nonstick properties, and its extremely low coefficient of friction. Because of these distinctive features, this material can be successfully employed in computer numerical control (CNC) machines where very smooth surfaces must be made with the greatest accuracy; such devices include those used for aerospace industry parts manufacturing, medical appliances production, or chemical handling equipment fabrication, among others.

Q: What are the advantages of using Teflon parts in machines?

A: There are several benefits associated with using Teflon parts within machines. Firstly, their low friction coefficient leads to minimal wearing out, thus reducing maintenance costs significantly over time. Secondly, they possess superior chemical resistance, thereby allowing them to be used even under harsh chemically corrosive environments without any degradation occurring on the part surface itself, unlike other common materials like metals, which may react adversely when exposed directly to certain chemicals over extended periods. Thirdly, these components exhibit excellent thermal stability and hence can operate continuously at elevated temperatures up to 260°C without losing physical integrity or becoming structurally damaged due to excessive heat generation from the surrounding environment. Additionally, non-stick nature simplifies cleaning procedures and ensures longer service life.

Q: Can PTFE be CNC machined into complex shapes, and what are the limitations?

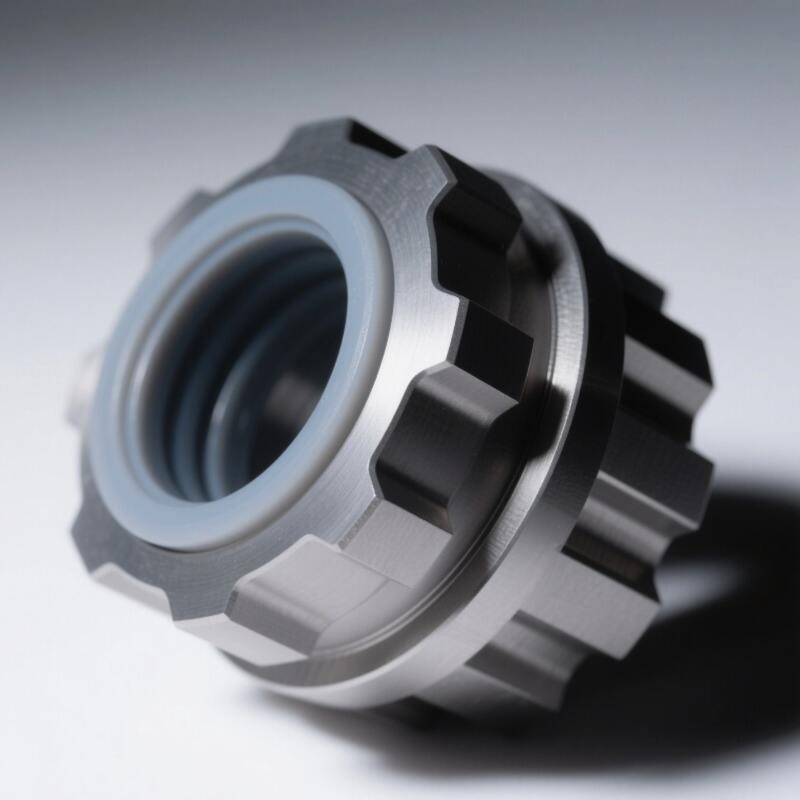

A: Certainly , PTFE can undergo various processes, including milling, drilling, turning, etc, so that intricate forms would become possible for realization through this technique alone . Good machinability provides opportunity more precise workmanship since tight tolerances could easily achieved during cnc operations performed directly on it . However, softness combined with flexibility vis-a-vis metals requires extra caution while carrying out such operations lest there should arise deformations along with dimensional inaccuracies that might otherwise be attributed to improper handling during the machining of any part made from Teflon.

Q: What effect does the process of machining have on the mechanical properties of Teflon parts?

A: The mechanical properties of Teflon parts can be changed by the process of machining; primarily surface finish and dimensional tolerance. These characteristics are achieved with precision machines like 5-axis CNC machine, which guarantees that materials meet strict requirements without necessarily changing their nature, such as a low friction coefficient and high chemical resistance, to name but a few. However, it is important for one to follow proper practices of machining so as not to lose these qualities.

Q: Which types of CNC machining services are recommended for use with Teflon?

A: Suitable forms include CNC milling, CNC turning, and 5-axis CNC machining among others. These services should be able to produce complicated shapes with close tolerances while leaving smooth surfaces intact, thus preserving beneficial features inherent in this material.

Q: How does the quality of machined Teflon parts rely on tool selection and settings made in CNC machines?

A: Quality depends largely upon tools used as well as setting made within machines themselves when dealing with Teflon during its processing phase into finished product through various stages such founding or shaping them later on into desired items depending on what each person wants achieve from such given processes therefore there are key things that need consideration points out; sharpness, maintenance levels before use, speeds rates fed rate depth cut etcetera all geared towards reducing burrs which normally cause poor finishes sometimes not netting required sizes dimensional accuracy might also be affected seriously so it is essential to choose correct parameters lest we compromise properties exhibited by these materials.

Q: Are there any special considerations for machining Teflon compared to metal and other plastics?

A: Yes, there are several unique factors involved when working with Teflon vis-a-vis metals or plastics. This indicates adjustment needs be done during strategies employed while undertaking this exercise so that no deformation happens due too much rubbing against each other causing displacement instead; lower feed rates may have to be adopted together with accurate tool paths plus supporting fixtures if tight tolerances have to be achieved otherwise good finishes won’t be realized at all. Additionally, designing fixtures should take into account the possibility of creeping under pressure during the cutting forces application stage because of its high elasticity.