Understanding Modern CNC Lathe Technology

The world of manufacturing has evolved dramatically with the advent of CNC lathe machining technology. This sophisticated approach to metalworking has revolutionized how we create precision parts and components. As we move toward 2025, understanding these fundamental concepts becomes increasingly crucial for anyone entering the manufacturing industry or looking to upgrade their production capabilities.

CNC lathe machining represents the perfect fusion of traditional turning operations with modern computer control, offering unprecedented accuracy and repeatability. This comprehensive guide will walk you through the essential aspects of CNC turning operations, from basic principles to practical applications, helping you build a solid foundation in this critical manufacturing technology.

Core Components of CNC Lathe Systems

Machine Structure and Base Components

The foundation of any CNC lathe machining system starts with its physical structure. The machine base, typically made from cast iron or polymer concrete, provides stability and vibration dampening essential for precise operations. The headstock houses the main spindle and drive system, while the tailstock offers additional workpiece support when needed.

Modern CNC lathes feature linear guideways, precision ball screws, and robust tool turrets that can hold multiple cutting tools. These components work together seamlessly to ensure accurate and repeatable machining operations. The integration of advanced sensors and feedback systems helps maintain tight tolerances throughout the manufacturing process.

Control Systems and Software Interface

The heart of CNC lathe machining lies in its control system. Modern machines utilize sophisticated controllers that interpret G-code programming to coordinate machine movements. These controllers feature user-friendly interfaces, often with graphical displays and simulation capabilities, making it easier for operators to set up and monitor machining operations.

Advanced control features include real-time tool monitoring, adaptive feed rate control, and automated error compensation. These systems can adjust cutting parameters on the fly, ensuring optimal performance and extending tool life while maintaining part quality.

Essential Operating Principles

Basic Turning Operations

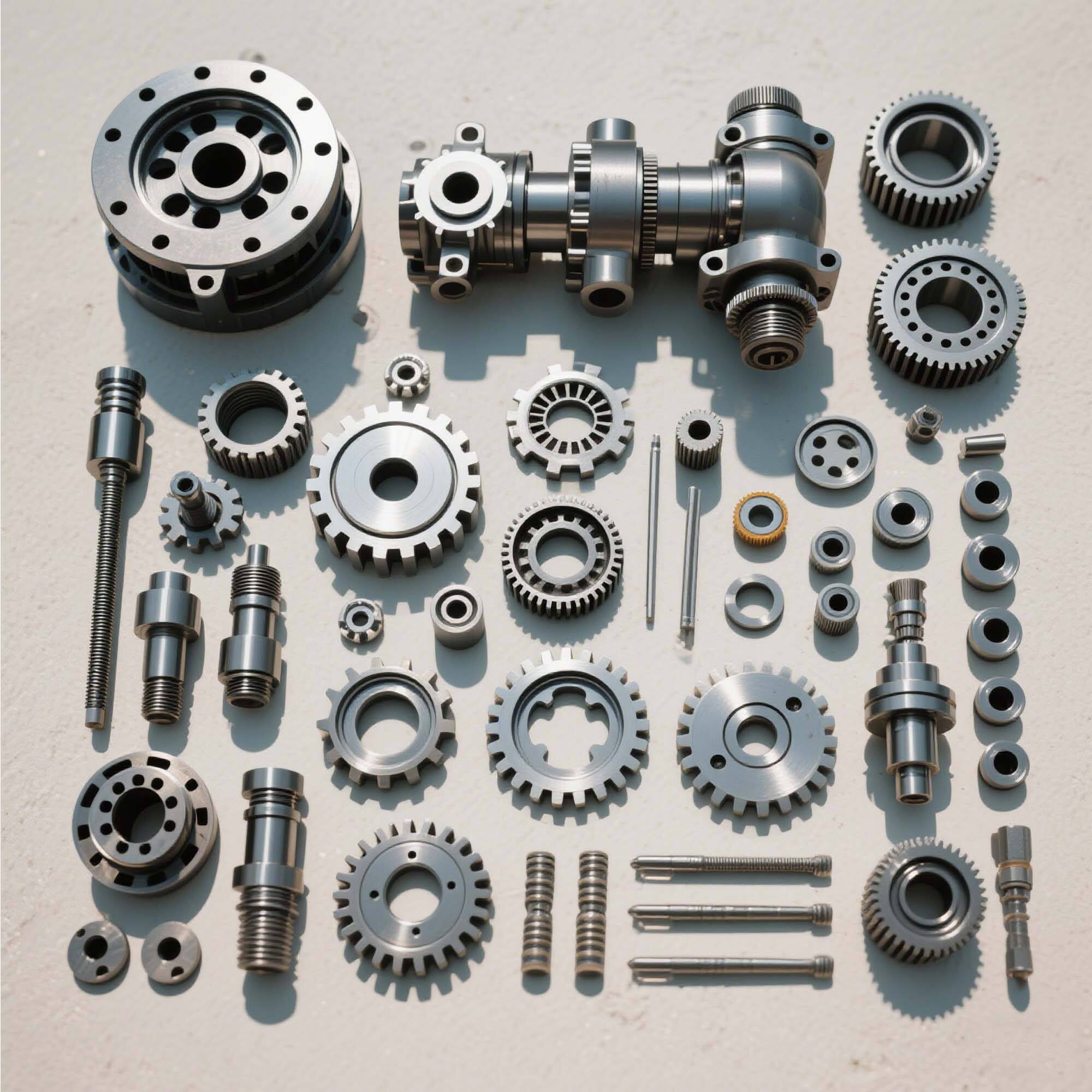

In CNC lathe machining, the fundamental operation involves rotating the workpiece while a cutting tool removes material to create the desired shape. Common operations include facing, turning, boring, and threading. Each of these operations requires specific tool selection and cutting parameters to achieve optimal results.

Modern CNC lathes can perform multiple operations in a single setup, significantly reducing production time and improving part consistency. The ability to maintain precise control over cutting speeds and feed rates ensures superior surface finish and dimensional accuracy.

Tool Selection and Management

Selecting the right cutting tools is crucial for successful CNC lathe machining. Modern insert tooling systems offer versatility and quick change capabilities, while solid carbide tools provide excellent performance for specific applications. Understanding tool geometry, cutting materials, and coating technologies helps optimize machining operations.

Tool management systems track tool life, predict wear patterns, and schedule replacements to minimize downtime. Advanced machines feature automatic tool measurement and compensation capabilities, ensuring consistent part quality throughout production runs.

Programming and Setup Procedures

G-Code Programming Fundamentals

While modern CAM software has simplified the programming process, understanding G-code basics remains essential for CNC lathe machining operations. Basic commands control machine movements, spindle speeds, feed rates, and tool changes. Operators should be familiar with common codes and their functions to troubleshoot programs effectively.

Modern programming techniques incorporate parametric programming and macro capabilities, allowing for more flexible and efficient code generation. These advanced features enable quick program modifications for different part variations while maintaining consistent machining strategies.

Workpiece Setup and Tool Offsetting

Proper workpiece setup is critical for successful CNC lathe machining. This includes selecting appropriate workholding devices, determining optimal cutting parameters, and setting tool offsets. Modern machines often feature probe systems for automated setup procedures, reducing setup time and potential errors.

Tool offset management ensures accurate machining results by compensating for tool wear and geometric variations. Advanced systems can automatically measure and update tool offsets, maintaining part accuracy throughout production runs.

Quality Control and Process Optimization

Measurement and Inspection Techniques

Quality control in CNC lathe machining requires regular part inspection and process monitoring. In-process measuring systems can verify critical dimensions during machining, while post-process inspection confirms final part quality. Modern inspection equipment includes CMMs, optical comparators, and sophisticated surface finish analyzers.

Statistical process control techniques help identify trends and potential issues before they affect part quality. This data-driven approach enables continuous process improvement and maintains consistent production quality.

Performance Optimization Strategies

Optimizing CNC lathe machining operations involves balancing productivity with part quality and tool life. Advanced cutting strategies, such as high-speed machining and optimized tool paths, can significantly improve cycle times while maintaining accuracy.

Regular maintenance procedures, including machine calibration and preventive maintenance, ensure consistent performance and minimize unexpected downtime. Implementing proper coolant management and chip control strategies also contributes to optimal machining results.

Frequently Asked Questions

What are the key advantages of CNC lathe machining over manual turning?

CNC lathe machining offers superior accuracy, repeatability, and productivity compared to manual operations. The computer control ensures consistent part quality, while automated tool changes and multi-axis capabilities enable complex parts to be produced efficiently in a single setup.

How long does it take to become proficient in CNC lathe programming?

With dedicated training and practice, operators can typically achieve basic proficiency in CNC lathe programming within 3-6 months. However, mastering advanced techniques and developing optimization skills usually requires 1-2 years of hands-on experience.

What maintenance procedures are essential for CNC lathes?

Regular maintenance includes daily cleaning, lubrication checks, coolant management, and tool inspection. Weekly or monthly tasks involve way lubrication, chuck maintenance, and calibration checks. Following the manufacturer's maintenance schedule is crucial for optimal machine performance and longevity.