The Evolution of Carbon Steel Processing in Modern Manufacturing

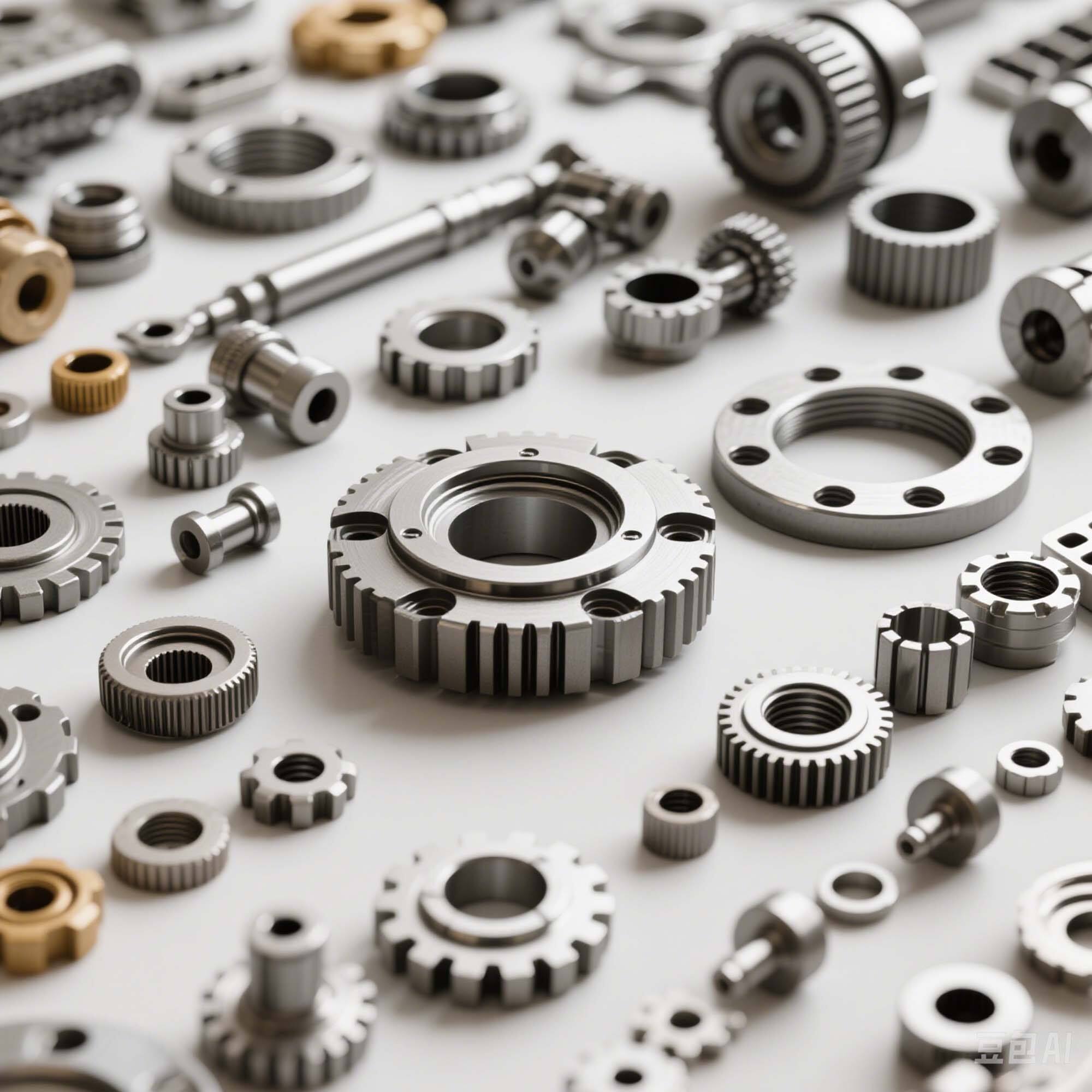

The intersection of precision machining and carbon steel has revolutionized modern manufacturing capabilities, enabling unprecedented levels of accuracy and reliability in critical industrial applications. From aerospace components to medical devices, precision machining carbon steel continues to push the boundaries of what's possible in engineering and manufacturing excellence.

Today's advanced machining processes have transformed how we approach carbon steel fabrication, moving far beyond traditional manufacturing methods to achieve tolerances measured in microns. This evolution represents a significant leap forward in our ability to create components that meet the most demanding specifications across various industries.

Understanding the Fundamentals of Carbon Steel Machining

Material Properties and Machining Considerations

Carbon steel's unique composition presents both opportunities and challenges in precision machining processes. The material's high strength, excellent wear resistance, and cost-effectiveness make it an ideal choice for numerous applications. However, these same properties require specific machining parameters to achieve optimal results.

The carbon content in steel significantly influences its machinability. Higher carbon content typically results in increased hardness and strength but can also lead to more challenging machining conditions. Understanding these material characteristics is crucial for selecting appropriate cutting tools, speeds, and feeds in precision machining carbon steel components.

Advanced Cutting Technologies and Techniques

Modern precision machining employs sophisticated cutting technologies specifically designed for carbon steel processing. Computer Numerical Control (CNC) systems, coupled with advanced cutting tools, enable manufacturers to achieve exceptional accuracy and surface finish quality. These technologies utilize optimized cutting geometries and coating technologies that extend tool life while maintaining precise dimensional control.

The implementation of high-speed machining strategies has particularly revolutionized carbon steel processing. These techniques reduce cutting forces and heat generation, resulting in better surface quality and improved dimensional accuracy. The careful selection of cutting parameters ensures consistent results while maximizing productivity.

Critical Applications Across Industries

Aerospace and Defense Components

In aerospace applications, precision machining carbon steel components must meet stringent safety and performance requirements. From landing gear components to structural elements, these parts demand exceptional accuracy and reliability. The aerospace industry relies on precision-machined carbon steel parts that can withstand extreme conditions while maintaining dimensional stability.

Defense applications present similarly demanding requirements, where components must perform flawlessly in challenging environments. Precision machining enables the production of complex geometries with tight tolerances, ensuring optimal performance in critical defense systems.

Medical Device Manufacturing

The medical industry depends on precision-machined carbon steel components for various applications, from surgical instruments to implant manufacturing equipment. The ability to produce components with exceptional surface finish and dimensional accuracy is crucial for ensuring patient safety and treatment effectiveness.

Medical device manufacturers leverage precision machining capabilities to create intricate features and complex geometries that would be impossible with conventional manufacturing methods. These components must meet strict regulatory requirements while maintaining consistent quality across production runs.

Quality Control and Validation Processes

Advanced Measurement and Inspection Techniques

Quality control in precision machining carbon steel components involves sophisticated measurement and inspection technologies. Coordinate Measuring Machines (CMM) and optical measurement systems provide detailed dimensional analysis, ensuring components meet exact specifications. These systems can detect deviations as small as a few microns, maintaining exceptional quality standards.

Real-time monitoring systems track machining parameters and tool conditions, allowing for immediate adjustments to maintain optimal cutting conditions. This proactive approach to quality control helps prevent defects and ensures consistent component quality.

Documentation and Traceability Requirements

Comprehensive documentation and traceability systems are essential aspects of precision machining operations. Each component's manufacturing history, including material certifications, process parameters, and inspection results, must be meticulously recorded and maintained. This documentation ensures compliance with industry standards and facilitates problem-solving when issues arise.

Modern manufacturing execution systems (MES) integrate quality control data with production information, providing complete traceability throughout the manufacturing process. This integration enables manufacturers to demonstrate compliance with customer requirements and regulatory standards.

Future Trends and Innovations

Digital Integration and Smart Manufacturing

The future of precision machining carbon steel lies in the integration of digital technologies and smart manufacturing principles. Industry 4.0 concepts, including artificial intelligence and machine learning, are being applied to optimize machining parameters and predict maintenance requirements. These advances promise to further improve accuracy and efficiency in carbon steel processing.

Digital twin technology is emerging as a powerful tool for simulating and optimizing machining processes before physical production begins. This capability reduces setup time and minimizes material waste while ensuring first-time-right manufacturing.

Sustainable Manufacturing Practices

Sustainability considerations are driving innovations in precision machining practices. Manufacturers are implementing more efficient cutting strategies and recycling programs to reduce environmental impact. Advanced cutting tool technologies and optimized machining parameters help minimize energy consumption while maintaining high precision standards.

The development of near-net-shape manufacturing techniques reduces material waste and machining time, contributing to more sustainable production practices. These innovations demonstrate the industry's commitment to environmental responsibility while maintaining exceptional quality standards.

Frequently Asked Questions

What are the key advantages of precision machining carbon steel?

Precision machining carbon steel offers several significant benefits, including exceptional dimensional accuracy, superior surface finish quality, and the ability to create complex geometries. The process ensures consistent quality across production runs while maintaining the material's inherent strength and durability properties.

How does carbon content affect machining processes?

The carbon content in steel directly influences its machinability characteristics. Higher carbon content typically results in increased hardness and strength but requires specific cutting parameters and tool selection. Understanding these relationships is crucial for achieving optimal machining results.

What quality control measures ensure precision in carbon steel machining?

Quality control in precision machining involves multiple layers of verification, including advanced measurement systems, real-time monitoring of machining parameters, and comprehensive documentation procedures. These measures ensure components meet exact specifications and comply with industry standards.