heat treatment

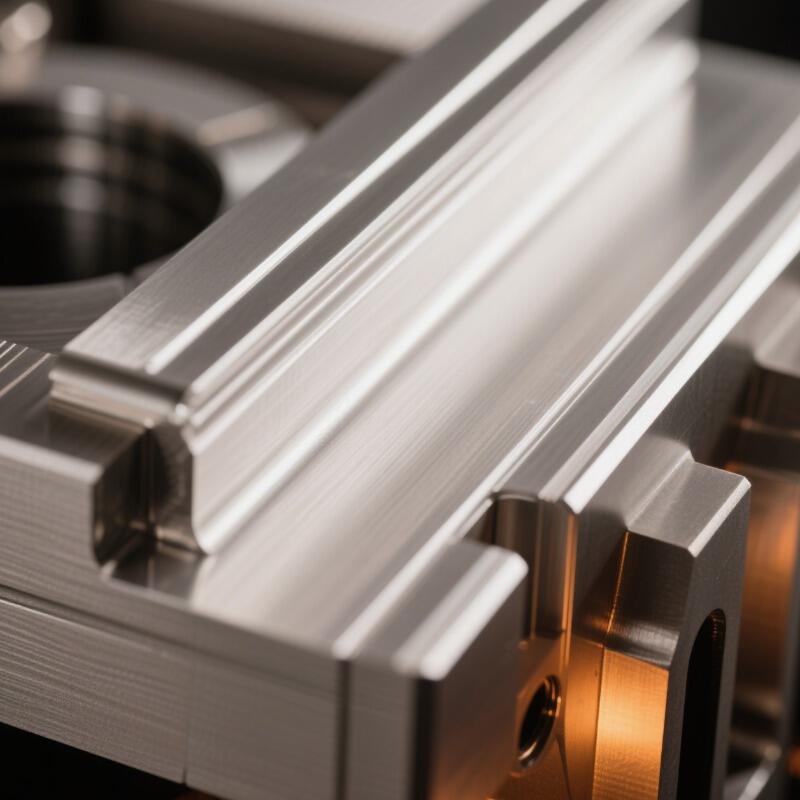

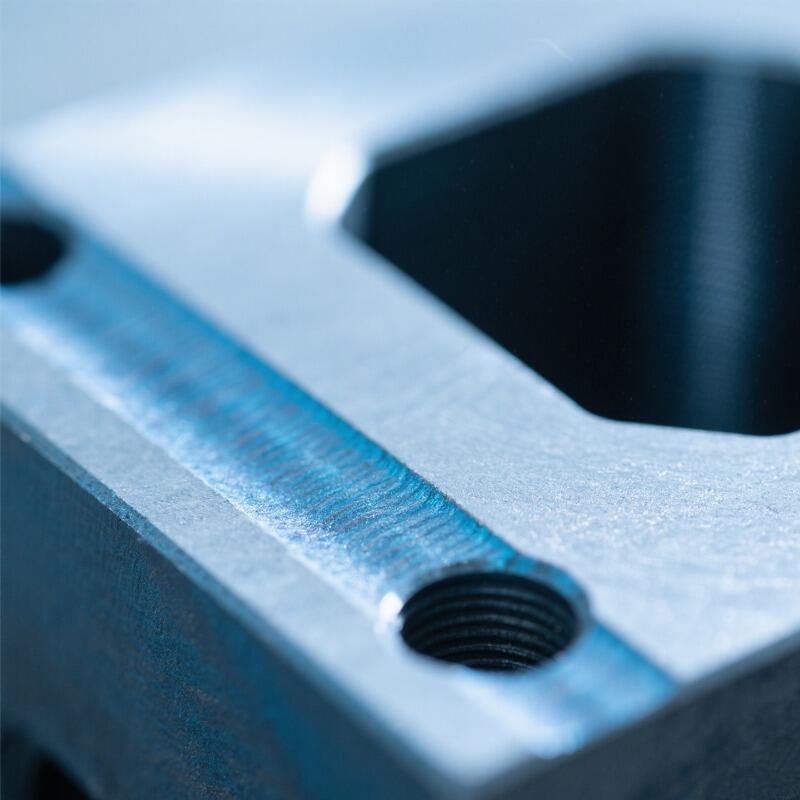

Heat treatment represents a controlled thermal process that fundamentally transforms the physical and mechanical properties of metals, alloys, and other materials through precise heating and cooling cycles. This sophisticated metallurgical technique involves subjecting materials to specific temperature ranges, maintaining those temperatures for predetermined periods, and implementing controlled cooling methods to achieve desired characteristics. The primary functions of heat treatment encompass enhancing material hardness, improving ductility, reducing internal stresses, refining grain structure, and optimizing overall mechanical performance. Modern heat treatment processes utilize advanced furnace technologies, precise temperature monitoring systems, and computer-controlled atmospheric conditions to ensure consistent results across various material types. The technological features of contemporary heat treatment include programmable heating profiles, inert gas atmospheres for oxidation prevention, rapid quenching systems, and automated handling equipment that minimizes human error while maximizing processing efficiency. Industries extensively employ heat treatment for manufacturing critical components in automotive applications, aerospace engineering, construction machinery, tool production, and electronic devices. The process accommodates diverse material categories including carbon steels, stainless steels, aluminum alloys, titanium alloys, and specialized superalloys used in extreme operating conditions. Heat treatment applications range from simple stress relief procedures for welded structures to complex multi-stage processes for high-performance turbine blades. The versatility of heat treatment allows manufacturers to tailor material properties precisely to specific application requirements, whether prioritizing wear resistance for cutting tools, corrosion resistance for marine components, or fatigue strength for rotating machinery. This fundamental manufacturing process continues evolving with technological advancements, incorporating energy-efficient heating methods, environmentally friendly quenching media, and real-time quality monitoring systems that ensure consistent product quality while reducing environmental impact and operational costs.