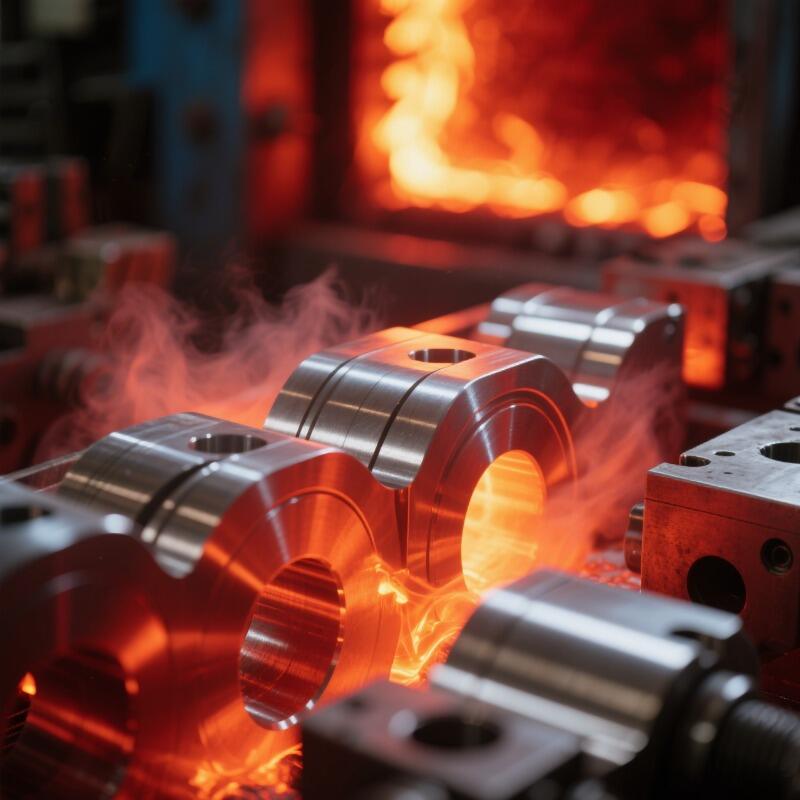

heat treatment of ferrous metals

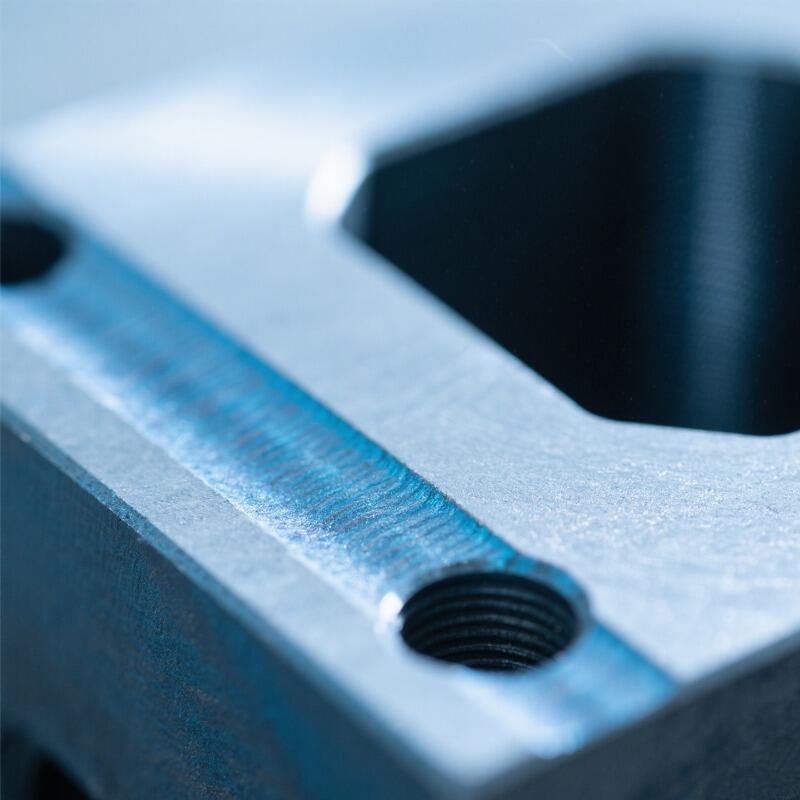

The heat treatment of ferrous metals represents a critical metallurgical process that fundamentally transforms the mechanical properties and structural characteristics of iron-based alloys through controlled heating and cooling cycles. This sophisticated technique manipulates the crystalline structure of steel, cast iron, and other ferrous materials to achieve desired properties such as enhanced strength, improved ductility, increased hardness, or superior wear resistance. The heat treatment of ferrous metals encompasses various methods including annealing, normalizing, hardening, tempering, and case hardening, each designed to meet specific engineering requirements. The primary functions of this process include stress relief, grain refinement, phase transformation, and microstructure modification. During heat treatment of ferrous metals, materials undergo thermal cycles that can reach temperatures exceeding 900°C, followed by controlled cooling rates that determine the final properties. The technological features of this process involve precise temperature control, atmosphere management, and timing coordination to ensure consistent results. Modern heat treatment facilities utilize advanced furnace systems with computerized controls that monitor temperature profiles, heating rates, and cooling parameters with exceptional accuracy. The applications of heat treatment of ferrous metals span across numerous industries including automotive manufacturing, aerospace engineering, construction, tool production, and machinery fabrication. Components such as gears, springs, cutting tools, structural beams, and engine parts routinely undergo heat treatment to optimize their performance characteristics. The versatility of this process allows manufacturers to tailor material properties to specific applications, whether requiring maximum hardness for cutting tools or enhanced toughness for structural components. The heat treatment of ferrous metals also plays a crucial role in extending component lifespan, reducing maintenance costs, and improving overall system reliability in demanding operational environments.