different types of heat treatment

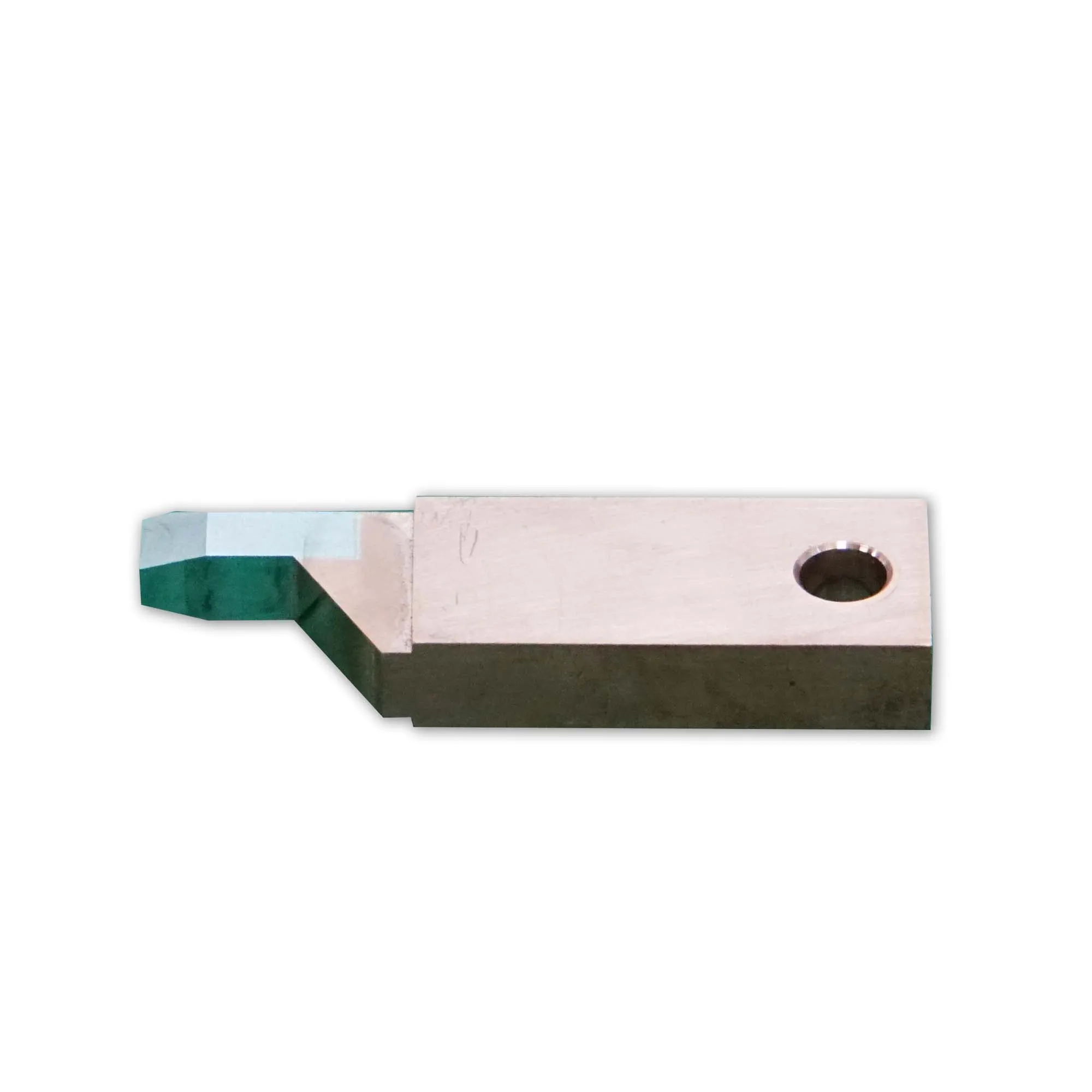

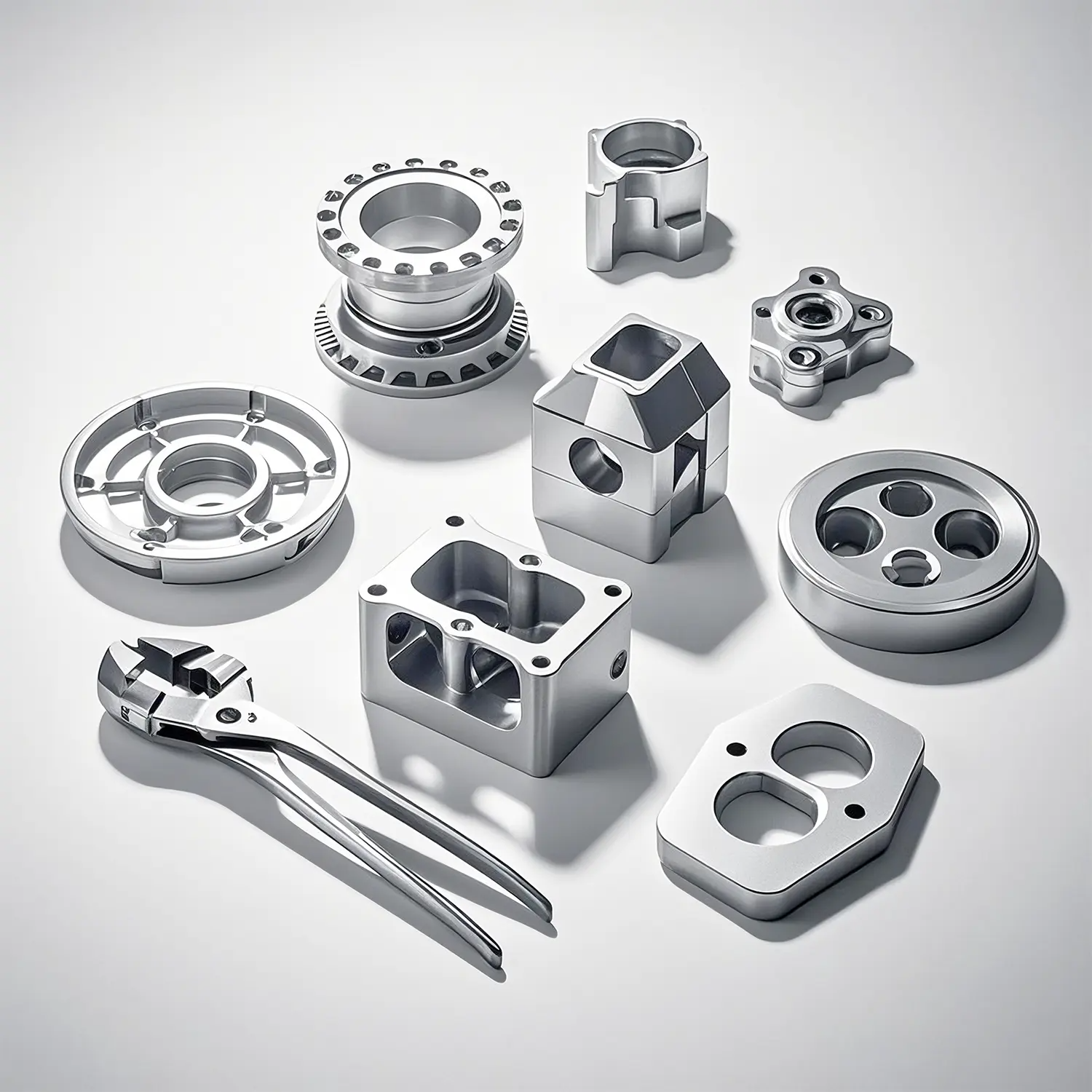

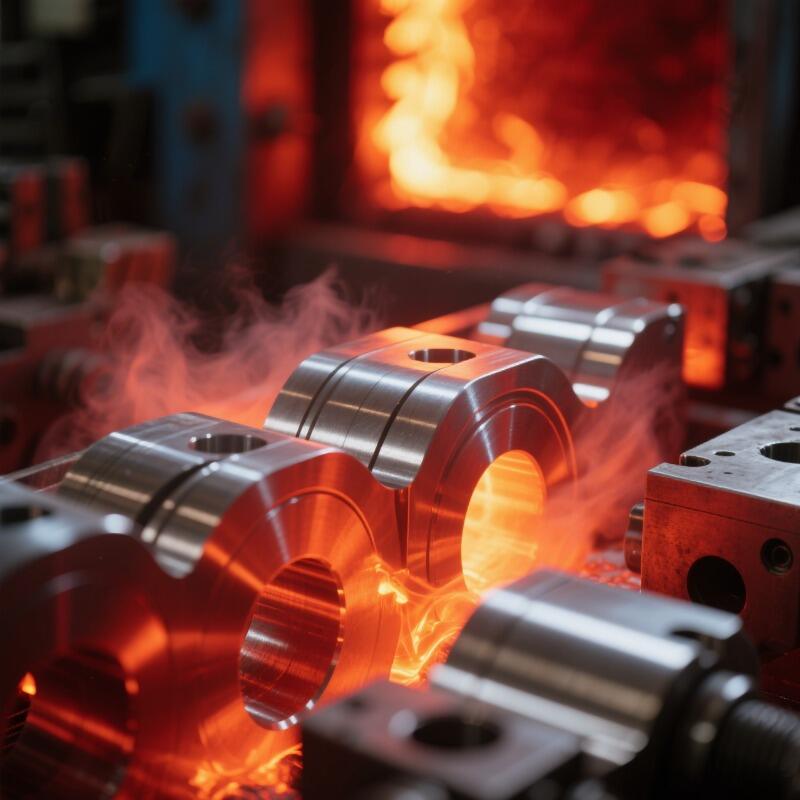

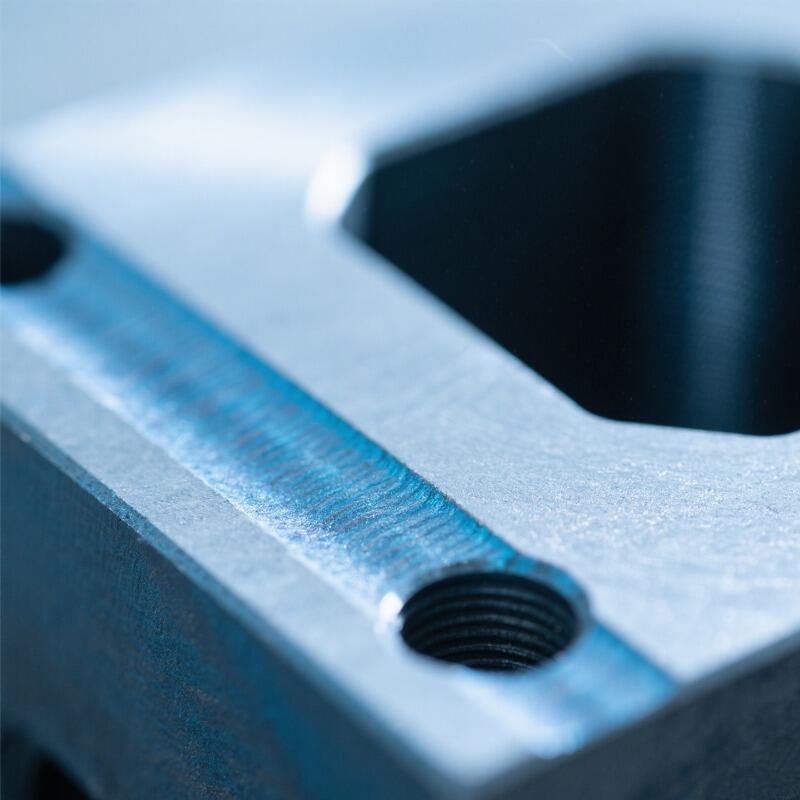

Heat treatment represents a crucial manufacturing process that involves controlled heating and cooling of metals to alter their physical and mechanical properties. Different types of heat treatment serve specific industrial purposes, each designed to enhance material characteristics according to application requirements. The primary categories include annealing, hardening, tempering, normalizing, and case hardening, each offering distinct technological advantages. Annealing involves heating metal to elevated temperatures followed by gradual cooling, effectively reducing internal stress and increasing ductility. This different types of heat treatment method proves essential for materials requiring enhanced workability and reduced brittleness. Hardening represents another fundamental approach where rapid cooling transforms metal structure, significantly increasing hardness and wear resistance. The technological features of hardening make it indispensable for cutting tools, gears, and high-stress components. Tempering follows hardening processes, providing controlled reheating that balances hardness with toughness, preventing catastrophic failure under operational stress. Normalizing offers uniform grain structure refinement through controlled heating and air cooling, ensuring consistent mechanical properties throughout the material. Case hardening creates surface-hardened layers while maintaining core toughness, ideal for components requiring wear resistance with impact tolerance. Different types of heat treatment applications span automotive manufacturing, aerospace engineering, construction equipment, and precision tooling industries. Each method employs specific temperature ranges, heating rates, and cooling procedures tailored to achieve desired metallurgical outcomes. Modern heat treatment facilities utilize advanced furnace technology, precise temperature control systems, and atmospheric management to ensure consistent results. The selection of appropriate different types of heat treatment depends on base material composition, desired final properties, component geometry, and service conditions. Quality control measures include hardness testing, microstructure analysis, and dimensional stability verification to validate treatment effectiveness.