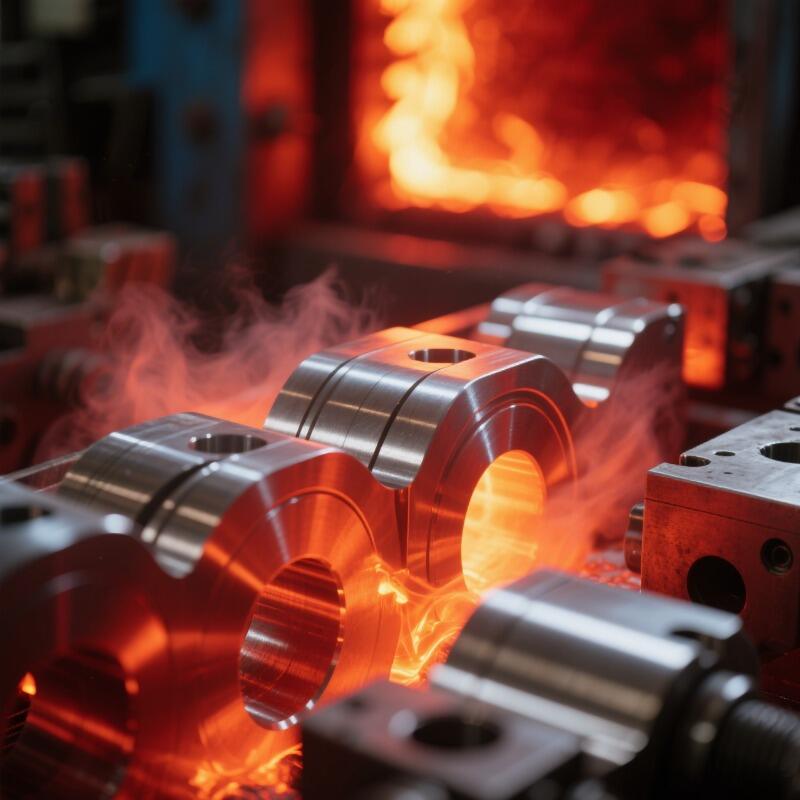

accurate heat treating

Accurate heat treating represents a sophisticated metallurgical process that transforms the physical and mechanical properties of metals through precise temperature control and timing protocols. This advanced manufacturing technique involves heating materials to specific temperatures, maintaining those temperatures for predetermined periods, and cooling them according to carefully engineered schedules. The primary functions of accurate heat treating encompass hardening, tempering, annealing, normalizing, and stress relieving operations that enhance material performance characteristics. Modern accurate heat treating systems utilize computer-controlled furnaces equipped with advanced monitoring sensors, programmable logic controllers, and data acquisition systems to ensure consistent results. The technological features include multi-zone temperature control, atmosphere management systems, quench media selection capabilities, and real-time process monitoring. These systems can achieve temperature accuracies within ±5°F while maintaining uniform heating throughout the workpiece. The process applications span across automotive components, aerospace parts, cutting tools, medical devices, industrial machinery, and precision instruments. Manufacturing facilities employ accurate heat treating to modify steel hardness levels, improve wear resistance, enhance fatigue strength, and optimize dimensional stability. The technology supports various material types including carbon steels, alloy steels, stainless steels, tool steels, and specialized superalloys. Quality control measures integrate thermocouples, pyrometers, and metallurgical testing equipment to validate treatment outcomes. The process parameters are documented through comprehensive record-keeping systems that track temperature profiles, timing sequences, and material certifications. Advanced accurate heat treating facilities often feature vacuum furnaces, inert gas atmospheres, and specialized quenchants to prevent oxidation and decarburization. This technology enables manufacturers to achieve specific mechanical properties such as tensile strength, yield strength, hardness values, and impact resistance according to engineering specifications.