Exceptional Versatility Across Critical Industry Applications

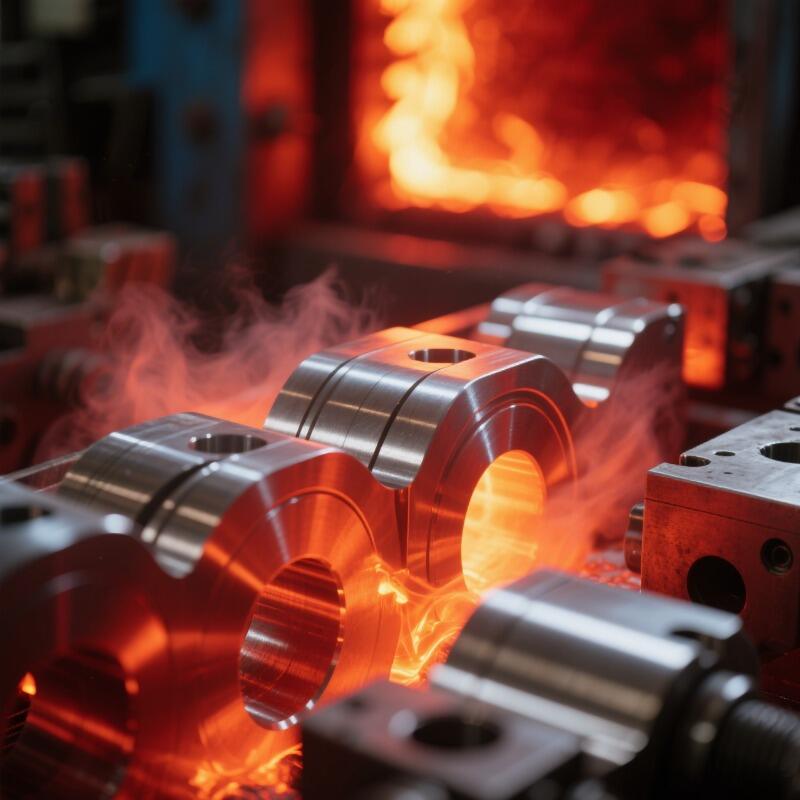

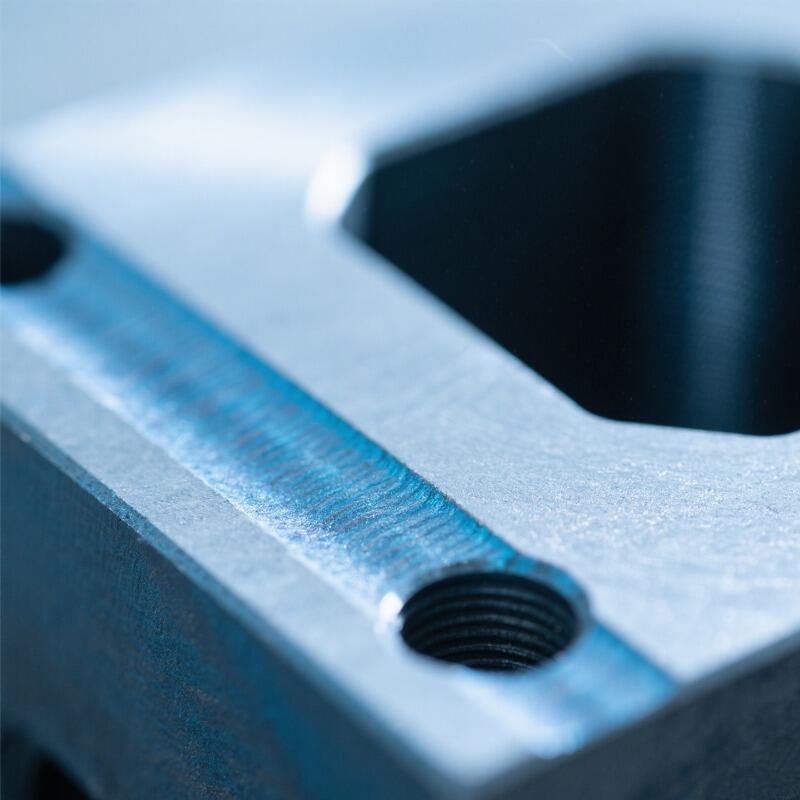

Heat treatable aluminium alloys demonstrate unparalleled versatility that makes them essential materials across diverse industries where performance, reliability, and efficiency are critical success factors. In aerospace applications, these alloys form the backbone of commercial and military aircraft structures, where their exceptional strength-to-weight ratios enable significant fuel efficiency improvements while maintaining stringent safety requirements. Aircraft manufacturers rely on heat treatable aluminium alloys for fuselage frames, wing spars, landing gear components, and engine mounts, where material failure could have catastrophic consequences. The automotive industry increasingly adopts these alloys for engine blocks, transmission housings, suspension components, and body panels, where weight reduction directly translates to improved fuel economy and reduced emissions without compromising crash safety performance. Marine applications benefit from the superior corrosion resistance of heat treatable aluminium alloys, particularly in saltwater environments where traditional materials would require extensive protective treatments. High-performance boats, offshore platforms, and naval vessels utilize these alloys for hulls, superstructures, and critical mechanical components that must withstand harsh marine conditions while minimizing maintenance requirements. The construction industry values heat treatable aluminium alloys for architectural applications including curtain walls, structural glazing systems, and specialized building components where strength, durability, and aesthetic appeal must coexist. Sporting goods manufacturers leverage these materials for bicycle frames, golf clubs, tennis rackets, and outdoor equipment where performance advantages can provide competitive benefits to end users. Electronic applications utilize the thermal management properties of heat treatable aluminium alloys for heat sinks, housings, and chassis components that must effectively dissipate heat while providing electromagnetic shielding. The precision machining capabilities of these alloys make them ideal for aerospace fasteners, automotive precision components, and medical devices where dimensional accuracy and surface finish are critical. This broad applicability demonstrates the fundamental value proposition of heat treatable aluminium alloys as enabling technologies across multiple industries.