spheroidizing heat treatment

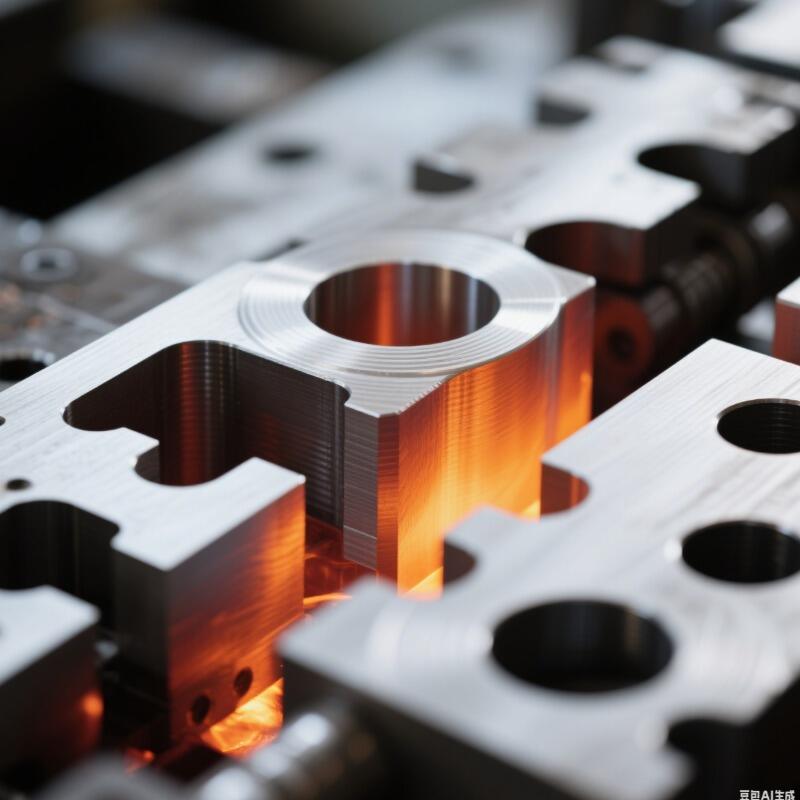

Spheroidizing heat treatment represents a specialized thermal processing technique designed to transform the microstructure of steel and other ferrous materials. This controlled heating and cooling process converts angular carbide particles into spherical shapes, fundamentally altering the material's mechanical properties. The spheroidizing heat treatment operates by heating steel to specific temperatures below the critical transformation point, typically between 650°C to 700°C, followed by controlled cooling cycles that promote carbide spheroidization. The primary function of spheroidizing heat treatment involves improving machinability, reducing hardness, and enhancing ductility in high-carbon steels. During this process, the lamellar pearlite structure transforms into spheroidal carbides distributed throughout a ferrite matrix, creating a more uniform and workable material. This transformation occurs through diffusion mechanisms that redistribute carbon atoms, allowing carbides to assume their thermodynamically favorable spherical configuration. The technological features of spheroidizing heat treatment include precise temperature control, extended holding periods, and carefully managed cooling rates. The process requires furnace atmospheres that prevent oxidation and decarburization, ensuring consistent results throughout the material cross-section. Applications for spheroidizing heat treatment span numerous industries, including automotive manufacturing, tool production, bearing fabrication, and precision machining operations. High-carbon tool steels, bearing steels, and spring steels particularly benefit from this treatment, as the spheroidal carbide structure significantly improves their formability and machinability. The aerospace industry utilizes spheroidizing heat treatment for critical components requiring exceptional dimensional stability and surface finish. Additionally, this process proves invaluable for preparing materials for subsequent cold forming operations, wire drawing, and complex machining procedures where improved plasticity becomes essential for successful manufacturing outcomes.