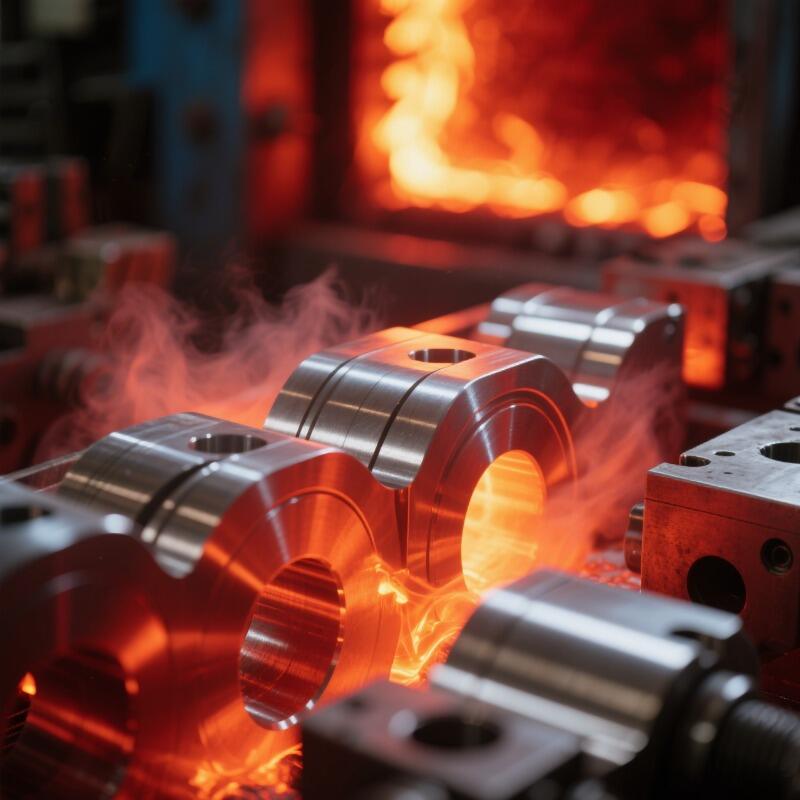

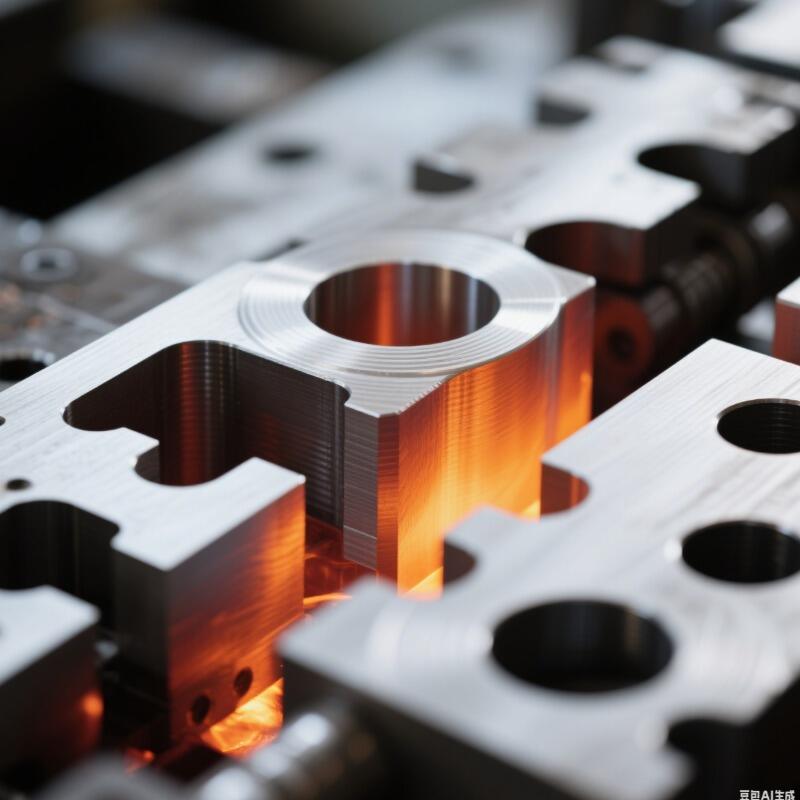

heat treatment of plain carbon steel

Heat treatment of plain carbon steel represents a fundamental metallurgical process that transforms the mechanical properties and microstructure of steel through controlled heating and cooling cycles. This sophisticated technique involves heating plain carbon steel to specific temperatures, maintaining that temperature for predetermined periods, and then cooling at controlled rates to achieve desired material characteristics. The heat treatment of plain carbon steel encompasses various processes including annealing, normalizing, hardening, and tempering, each serving distinct purposes in optimizing steel performance. During annealing, plain carbon steel undergoes softening through stress relief and grain refinement, making it more workable for subsequent manufacturing operations. Normalizing involves heating the steel above its critical temperature followed by air cooling, which refines grain structure and improves mechanical properties. Hardening increases strength and wear resistance by rapid cooling from high temperatures, creating martensitic structures within the steel matrix. Tempering reduces brittleness while maintaining acceptable hardness levels through controlled reheating processes. The technological features of heat treatment of plain carbon steel depend heavily on carbon content, with low carbon steels requiring different parameters than medium or high carbon variants. Temperature control remains critical, as precise heating ensures uniform transformation throughout the steel cross-section. Cooling rate manipulation allows metallurgists to control final microstructures and resulting mechanical properties. Time at temperature influences grain growth and carbide precipitation, directly affecting final steel characteristics. Applications span numerous industries including automotive manufacturing, construction, tool production, and machinery fabrication. Automotive components benefit from heat treatment of plain carbon steel through enhanced durability and performance reliability. Construction applications utilize treated steel for structural integrity and longevity. Tool manufacturing relies on heat treatment processes to achieve optimal hardness and wear resistance combinations essential for cutting applications.