salt bath annealing

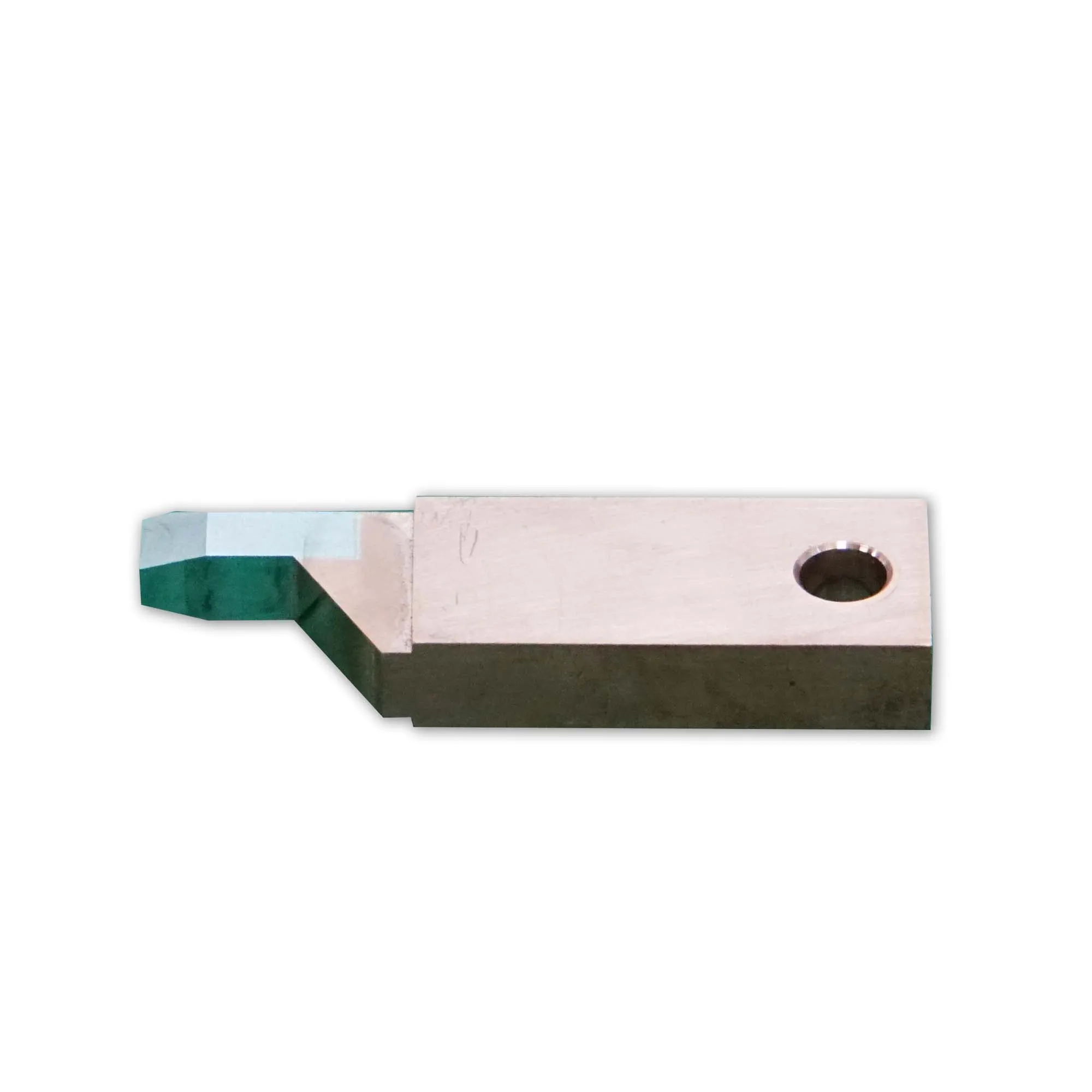

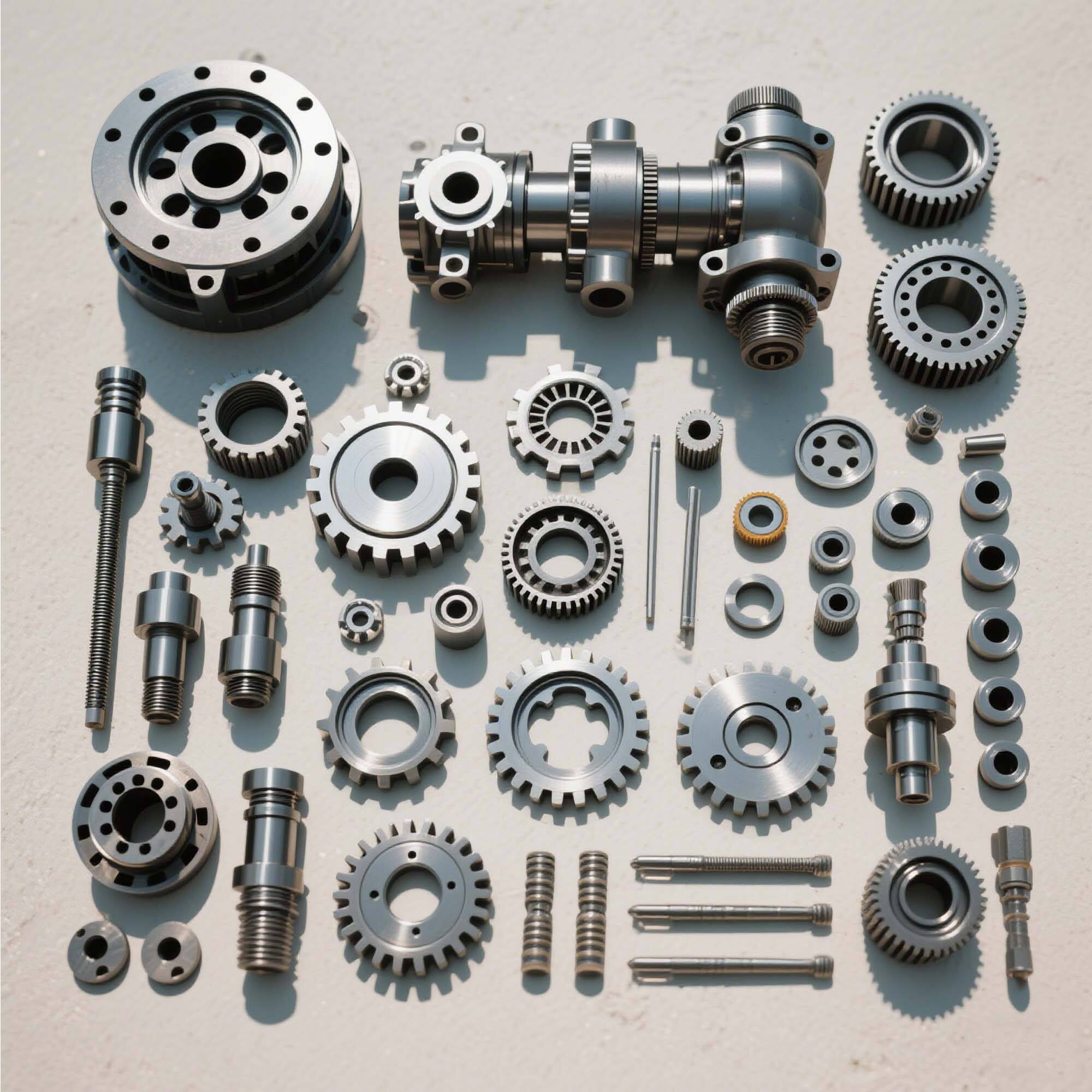

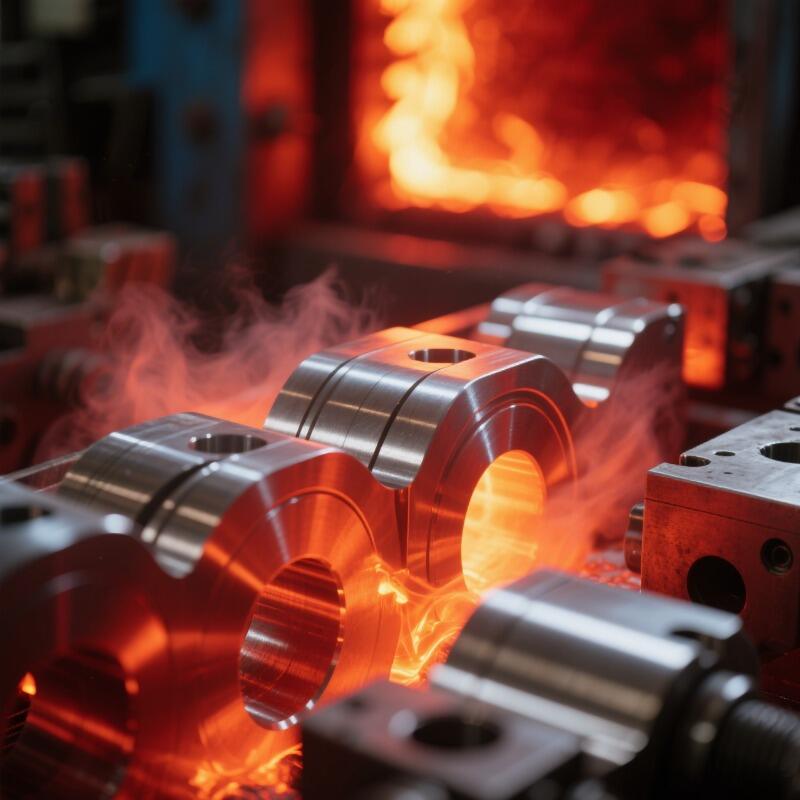

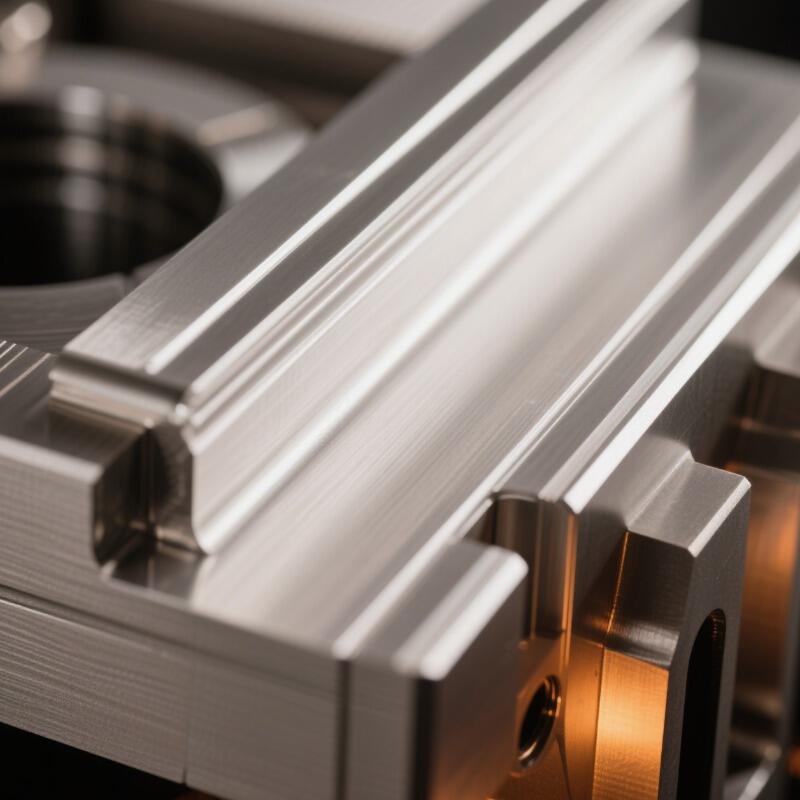

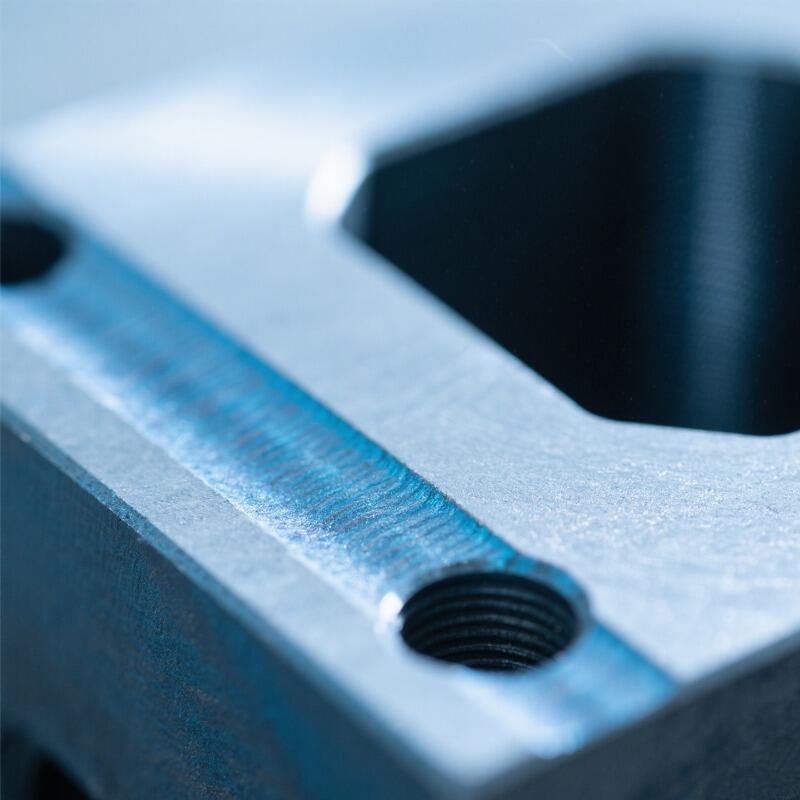

Salt bath annealing represents a sophisticated heat treatment process that utilizes molten salt as the heating medium to achieve precise temperature control and uniform heat distribution throughout metal components. This advanced metallurgical technique involves immersing steel parts, tools, or other metal workpieces into carefully controlled molten salt baths maintained at specific temperatures ranging from 300°C to 1200°C depending on the material requirements and desired outcomes. The salt bath annealing process serves multiple critical functions in modern manufacturing, including stress relief, grain structure refinement, hardness reduction, and improvement of mechanical properties such as ductility and machinability. The technological features of salt bath annealing distinguish it from conventional furnace-based annealing methods through its exceptional temperature uniformity, rapid heating rates, and precise atmosphere control. The molten salt medium provides intimate contact with all surfaces of the workpiece, ensuring consistent heat transfer and eliminating temperature gradients that commonly occur in gas or electric furnaces. This uniform heating characteristic makes salt bath annealing particularly valuable for complex geometries, thin sections, and precision components where dimensional stability and consistent material properties are paramount. The process applications span across diverse industries including automotive manufacturing, aerospace engineering, tool and die production, and precision machining operations. Salt bath annealing proves especially beneficial for treating high-speed steel cutting tools, where controlled heating and cooling cycles restore optimal cutting performance while extending tool life. The automotive sector leverages this technology for processing transmission components, engine parts, and suspension elements that require specific hardness profiles and stress relief patterns. Aerospace applications utilize salt bath annealing for critical components subjected to extreme operating conditions, where material reliability and performance consistency directly impact safety and operational efficiency. The controlled atmosphere within the salt bath prevents oxidation and decarburization, maintaining surface integrity while achieving desired metallurgical transformations throughout the component cross-section.