pre heat treatment

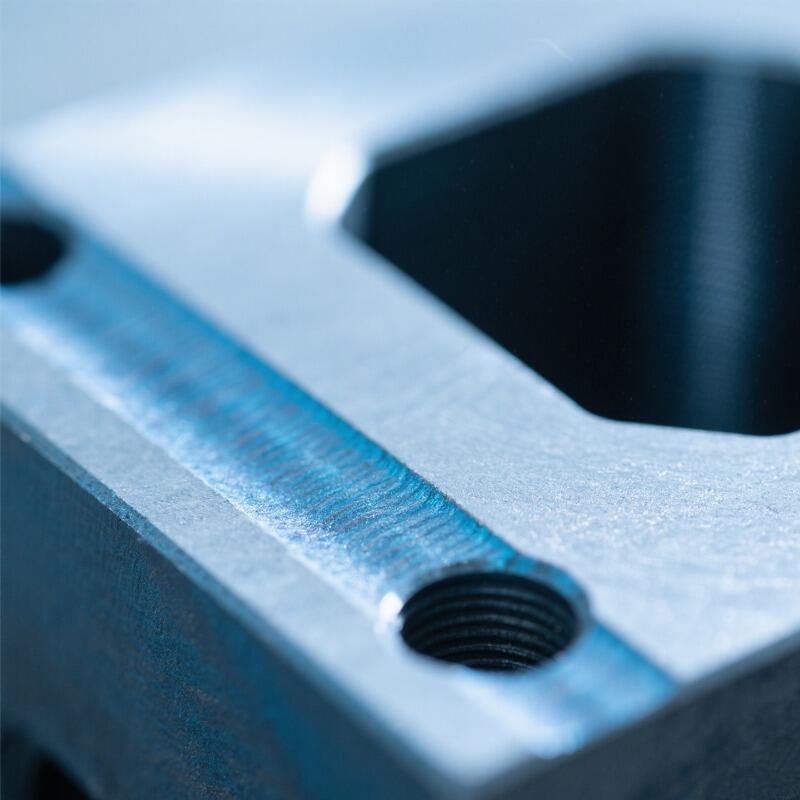

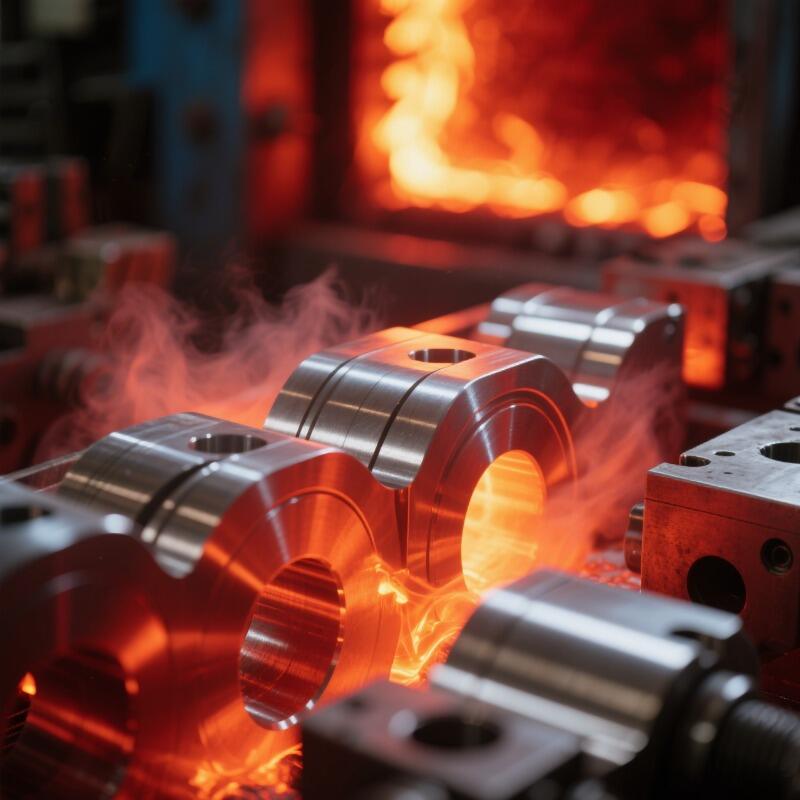

Pre heat treatment represents a fundamental thermal processing technique that prepares materials for subsequent manufacturing operations or final applications. This essential metallurgical process involves controlled heating of metals, alloys, and other materials to specific temperatures below their melting points, followed by carefully managed cooling cycles. The primary purpose of pre heat treatment is to modify the internal structure and properties of materials, making them more suitable for further processing or end-use applications. During this process, materials undergo controlled thermal cycles that alter their crystalline structure, grain boundaries, and internal stress patterns. The temperature ranges and time durations vary significantly depending on the material type, desired properties, and intended applications. Pre heat treatment serves multiple critical functions in manufacturing and materials engineering. It reduces internal stresses that develop during casting, forging, or machining operations, preventing potential cracking or dimensional instability. The process also improves machinability by softening hard materials, making them easier to cut, drill, or shape during subsequent manufacturing steps. Additionally, pre heat treatment enhances the uniformity of material properties throughout the workpiece, eliminating inconsistencies that could compromise final product quality. The technological features of pre heat treatment include precise temperature control systems, controlled atmosphere environments, and sophisticated monitoring equipment. Modern pre heat treatment facilities utilize advanced furnace technologies with programmable temperature profiles, ensuring consistent and repeatable results. Atmosphere control prevents oxidation and contamination during heating, while real-time monitoring systems track temperature distribution and heating rates. Applications span across numerous industries including automotive, aerospace, construction, and manufacturing. Components such as engine blocks, structural steel, cutting tools, and precision machinery parts benefit from pre heat treatment processes. The versatility of this technique makes it indispensable for achieving desired material characteristics in diverse manufacturing environments.