Essential Strategies for Maximizing CNC Equipment Longevity

CNC machine maintenance stands at the core of manufacturing efficiency and productivity. In today's competitive industrial landscape, maintaining precision equipment isn't just about fixing problems as they arise – it's about implementing comprehensive strategies that prevent issues before they occur. Well-maintained CNC machines not only deliver superior performance but also ensure consistent quality output while minimizing costly downtime.

Manufacturing facilities worldwide rely on CNC machinery for their daily operations, making proper maintenance protocols essential for sustainable production. The intricate nature of these sophisticated machines demands a thorough understanding of wear patterns, replacement schedules, and preventive care measures to maintain optimal functionality.

Understanding CNC Machine Components and Wear Patterns

Critical Components Requiring Regular Attention

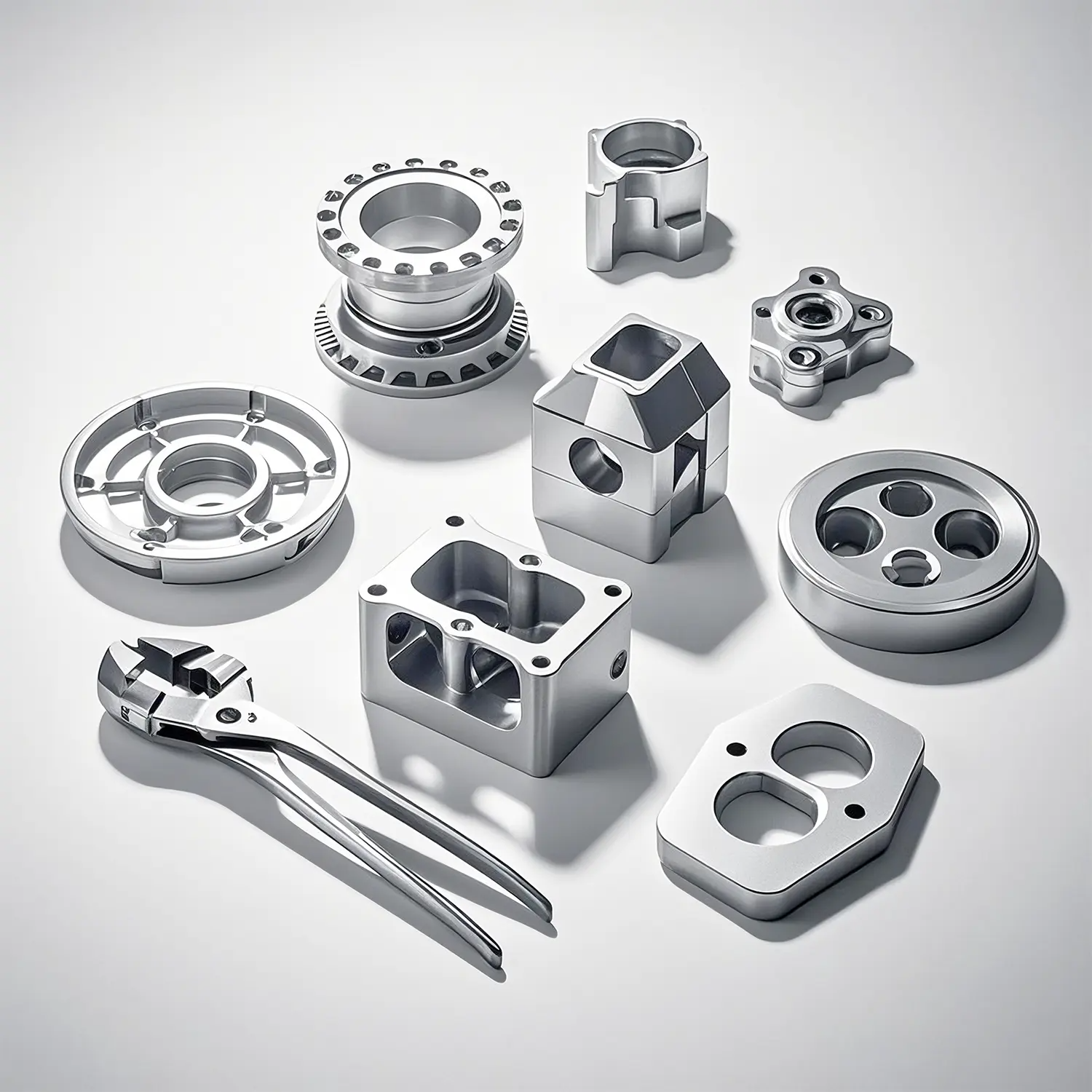

The heart of any CNC machine consists of several vital components that require consistent monitoring. Spindles, ball screws, and guide ways form the foundation of machine movement and precision. These components experience varying degrees of wear based on usage patterns, material types processed, and operating conditions. Regular inspection of these elements helps identify early signs of deterioration.

Tool holders, cutting implements, and coolant systems also demand careful attention. The accuracy of machined parts directly correlates with the condition of these components. Understanding their typical lifespan and wear indicators enables maintenance teams to schedule replacements before failure occurs.

Common Wear Patterns and Their Implications

Different machine components exhibit distinct wear patterns that skilled technicians must recognize. Spindle bearings may show signs of excessive vibration or unusual noise before complete failure. Ball screws often display increased backlash or inconsistent movement when wear becomes significant. Guide ways might develop uneven wear patterns that affect machine accuracy.

Environmental factors, such as temperature fluctuations and dust exposure, can accelerate wear rates. Monitoring these patterns helps establish more accurate maintenance schedules tailored to specific operating conditions. Regular documentation of wear progression supports better prediction of component life cycles.

Implementing Preventive Maintenance Protocols

Daily and Weekly Maintenance Tasks

Effective CNC machine maintenance begins with routine daily checks. Operators should inspect coolant levels, check for unusual noises or vibrations, and ensure proper lubrication of moving parts. Weekly tasks might include more thorough cleaning of filters, inspection of tool wear, and verification of axis alignment.

Documentation plays a crucial role in daily maintenance. Maintaining detailed logs of inspections, unusual observations, and minor adjustments helps track machine health over time. These records become invaluable for identifying patterns and predicting potential issues before they escalate.

Monthly and Quarterly Maintenance Procedures

More comprehensive maintenance procedures should be scheduled monthly and quarterly. These include detailed inspection of electrical systems, thorough cleaning of hard-to-reach areas, and verification of geometric accuracy. Calibration checks ensure the machine maintains required precision levels.

During these scheduled maintenance periods, technicians should also evaluate the condition of wearing parts against established benchmarks. This helps determine if replacement schedules need adjustment based on actual wear rates rather than just predetermined timeframes.

Advanced Monitoring and Predictive Maintenance

Utilizing Modern Diagnostic Tools

Today's CNC machine maintenance benefits from sophisticated monitoring tools and sensors. Vibration analysis equipment can detect bearing issues before they become audible. Thermal imaging cameras identify potential hot spots that might indicate developing problems. These advanced diagnostic tools provide valuable data for predictive maintenance programs.

Integration of machine monitoring software allows for real-time tracking of performance metrics. This data-driven approach enables maintenance teams to spot trends and anomalies that might otherwise go unnoticed until significant problems develop.

Data-Driven Maintenance Planning

Modern maintenance strategies increasingly rely on data analytics to optimize replacement schedules. By analyzing performance data, maintenance teams can identify patterns that precede component failure. This information helps refine preventive maintenance schedules and reduce unexpected downtime.

Predictive analytics can also help optimize spare parts inventory management. By better understanding wear patterns and replacement cycles, facilities can maintain appropriate stock levels without excessive inventory costs.

Part Replacement Strategies and Best Practices

Timing Replacement Decisions

Successful CNC machine maintenance requires strategic timing of part replacements. Rather than waiting for complete failure, components should be replaced based on performance degradation indicators and historical data. This proactive approach minimizes unexpected downtime and maintains consistent production quality.

Maintenance managers must balance the cost of early replacement against the risk of failure during production. Developing clear criteria for replacement decisions helps standardize this process across maintenance teams and shifts.

Sourcing Quality Replacement Parts

The quality of replacement parts significantly impacts machine performance and reliability. While original equipment manufacturer (OEM) parts often provide the highest reliability, carefully evaluated alternative sources may offer cost advantages without compromising quality. Establishing relationships with reliable suppliers ensures consistent access to quality components.

Creating a comprehensive parts database helps track supplier performance, cost trends, and part reliability over time. This information proves invaluable for making informed decisions about future purchases and supplier selection.

Frequently Asked Questions

How often should CNC machine calibration be performed?

CNC machine calibration frequency depends on usage patterns and precision requirements. Generally, full geometric calibration should be performed quarterly, with more frequent checks of critical dimensions. High-precision applications may require monthly verification of key parameters.

What are the signs that spindle bearings need replacement?

Key indicators include unusual noise during operation, excessive vibration, decreased accuracy in machined parts, and abnormal temperature readings. Regular vibration analysis can help detect bearing issues before they cause significant problems.

How can I optimize my spare parts inventory?

Maintain detailed records of part usage and failure rates to establish appropriate stock levels. Consider lead times for critical components and implement a system for tracking inventory. Use predictive maintenance data to anticipate needs and adjust stock levels accordingly.