stabilization heat treatment

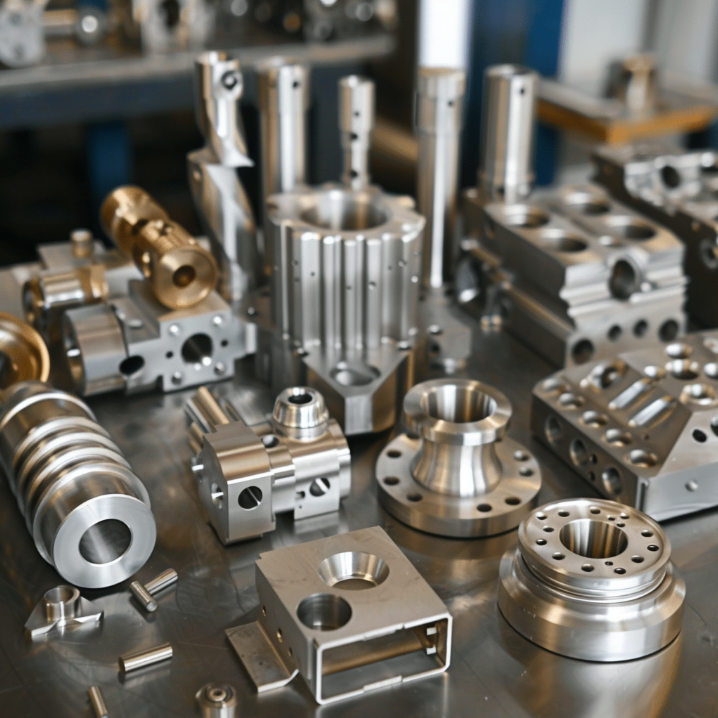

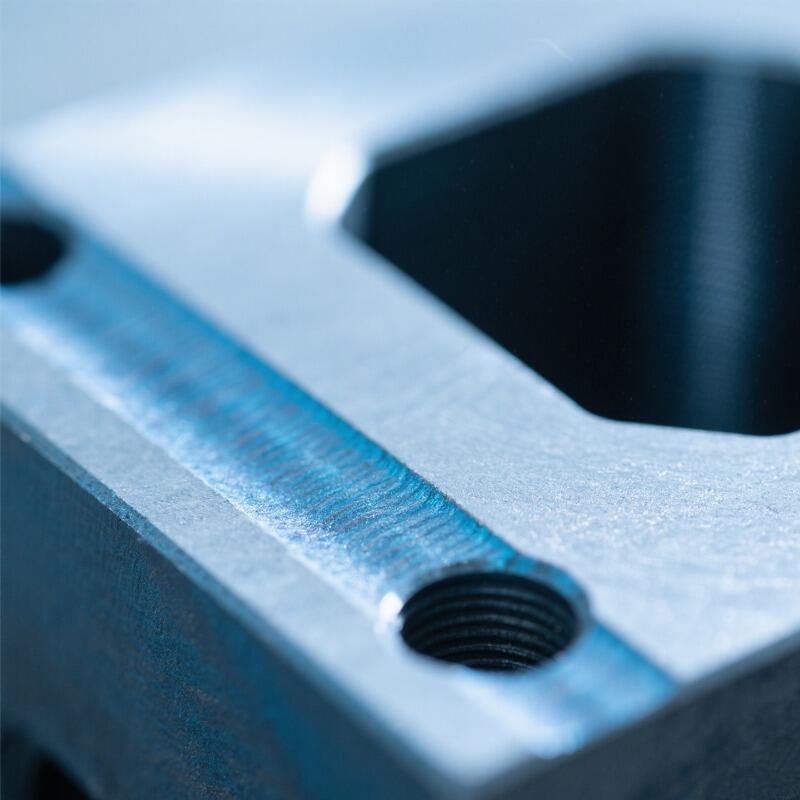

Stabilization heat treatment represents a crucial metallurgical process designed to enhance the dimensional stability and mechanical properties of metallic components through controlled thermal processing. This specialized treatment involves heating materials to specific temperatures followed by controlled cooling cycles to achieve desired microstructural changes. The stabilization heat treatment process serves multiple critical functions in manufacturing, including stress relief, dimensional stabilization, and microstructural refinement. The primary objective of this treatment is to eliminate internal stresses that develop during manufacturing processes such as machining, welding, or forming operations. These residual stresses can cause unwanted dimensional changes over time, leading to component failure or performance degradation. The technological features of stabilization heat treatment include precise temperature control, controlled heating rates, and specific holding times at target temperatures. The process typically operates within temperature ranges that are carefully selected based on material composition and desired outcomes. Modern stabilization heat treatment facilities utilize advanced furnace systems with programmable temperature controllers, ensuring consistent and repeatable results. The treatment atmosphere can be controlled to prevent oxidation or decarburization, maintaining surface quality and chemical composition. Applications of stabilization heat treatment span across numerous industries, including aerospace, automotive, precision machinery, and tool manufacturing. In aerospace applications, critical components such as landing gear parts, engine components, and structural elements undergo stabilization heat treatment to ensure dimensional accuracy and reliability under extreme operating conditions. The automotive industry employs this treatment for transmission components, engine blocks, and precision measuring instruments. Manufacturing sectors utilize stabilization heat treatment for machine tool components, measuring equipment, and high-precision fixtures where dimensional stability is paramount for operational effectiveness and long-term performance reliability.