5. Timely Delivery: Expect punctuality and efficiency from us as we ensure that all our projects are completed on time – this also applies to CNC grinding processes.

Frequently Asked Questions

If you want to know more about CNC Milling Service

Q: What are the potential materials for CNC machining?

A: Metals and plastics comprise a majority of the materials used in CNC machining. Aluminum, steel, brass, and copper are common metals while ABS, polycarbonate, nylon, and PEEK are frequently machined plastics. Different physical properties need to be considered such as strength, thermal resistance, and cost when selecting materials for cnc machined parts.

Q: How do I request a quote for custom CNC machining services?

A: To request a quote from a custom CNC machine shop you usually need to share specific information about your project with them. This includes providing 3D CAD models of parts to be machined along with selected material types, quantities desired finishing requirements if any. Many online providers have instant quoting systems where you can upload these details and get an immediate price estimate.

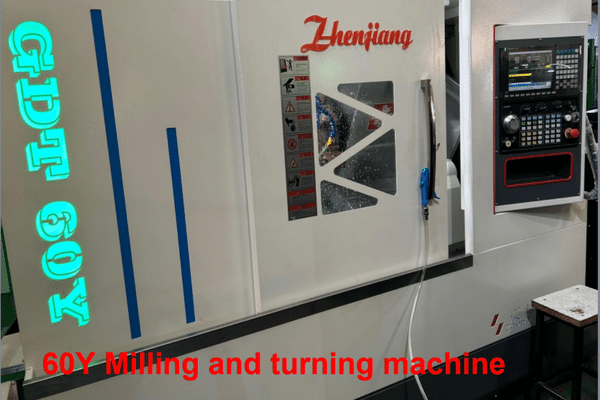

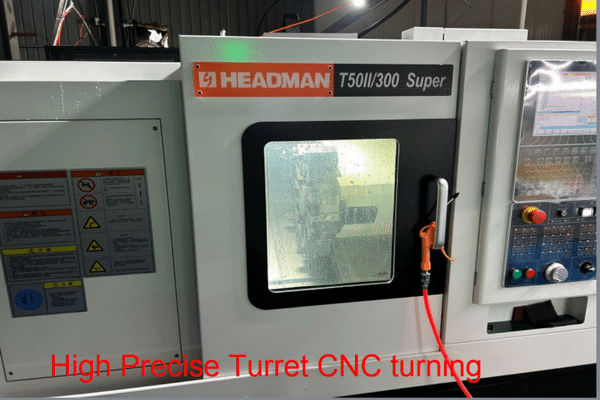

Q: What is the distinction between CNC milling and turning?

A: The main difference between milling machines (mills) and lathes (turning centers) lies within their method of material removal from workpieces; namely which component remains stationary while another moves relative to it cutting away excess stock material until desired shape achieved. In other words – what doesn’t move during cutting? For example imagine removing metal shavings with fixed drill bit versus having rotating cutter head against bolt stock – that’s difference explained!

Q: Could you describe how does cnc machining work?

A: The process of computer numerical control (CNC) machining involves using software programs to guide machines through specific actions necessary for shaping raw materials like plastics or metals into finished products; objects made by this system are often referred to as “parts” since they’re typically components within larger assemblies (e.g., car engines). In order words – what happens stepwise during each operation performed on block/blank until final form achieved? Start off by designing CAD model which represents end part should look alike once completed then convert it into instructions readable by cnc machine. The cutter follows these commands to cut, drill, or turn the material while taking into account the desired process (milling, turning, or both) and transforming it from its raw form into a precise custom part.

Q: What are the primary uses of CNC machining?

A: CNC machining applications cut across various industries like aerospace, automotive, medical, electronics and many more. They are normally used in making intricate parts that require high precision with good surface finish for example engine components, medical implants among others. The ability to offer different services makes it possible for one-off custom projects as well as large scale production runs of custom cnc parts.

Q: How long does it take to get parts made by a CNC machine shop?

A: The time it takes to receive parts from a CNC machine shop depends on many things. These include; how complex the design is (or number of designs), current workload at that particular machine shop floor space occupied by machines doing jobs this is determined mainly by number orders they have received plus their own operational capacity based on type equipment they possess , specific skills available within said business establishment that can be utilized during different stages in production process such as programming skills etc.. Among these factors also includes availability of materials being machined and finally skill level programmed into each particular job being done plus capabilities those machines being used themselves. However, some cnc machine shops offer same day delivery on prototypes thanks efficient manufacturing processes.

Q: How do precision cnc milling service ensure quality control measures are met when producing machined parts?

A: Quality control measures at precision cnc milling service centers are ensured through combination advanced machining capabilities and skilled technicians who operate them under strict conditions set in place to ensure compliance with standards required by industry regulatory bodies . This involves use of precision cnc milling machines equipped with highly accurate cutting tools where regular tooling maintenance must be carried out periodically so as not only keep them working optimally but also maintain accuracy levels expected from such equipment during their lifespan besides this thorough inspection checks should performed at every stage machining process which include before during after completion just make sure everything goes according plan without any errors cropping up along way . Some shops also go further to obtain additional certification.

Q: Can I use CNC machining for prototyping as well as production runs?

A: Yes, CNC machining is capable of manufacturing both prototypes and production parts. Prototyping requires an accurate representation of the final product, which can be achieved by using this process due to its high accuracy in dimensional tolerances, finishes, and other needed for efficient testing validation. On the other hand, its scalability allows it to be used to make custom CNC parts in small quantities and large quantities with the same level of quality.

Q: What cannot be achieved with CNC technology?

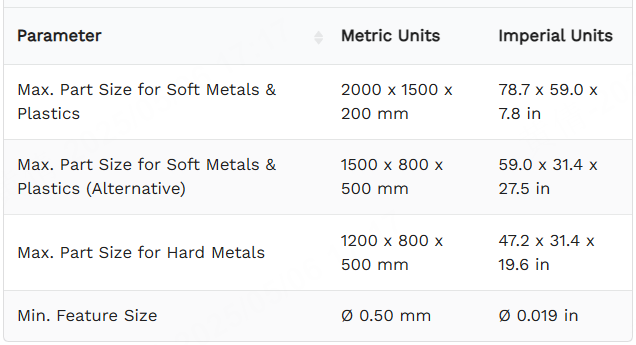

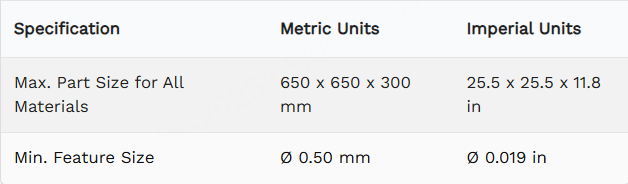

A: While it has a wide range of functions, there are things that cannot be done with CNC technology. Complex designs may not work well because some features might have too many steps or angles involved which makes them difficult to manufacture through conventional means; at times size does matter so much especially when dealing with bigger components than what given machine tooling allows for example mill bed length could limit size part being machined thereby restricting dimensions produced but now all these limitations are set aside since 5-axis machines were introduced into market giving greater capabilities than before